In the world of underground cable installation, efficiency plays a crucial role. The use of an "Underground Cable Pulling Sock" can significantly enhance this process. Industry expert John Smith, a renowned cable installation specialist, once stated, "Using the right tools can transform a challenging job into a manageable task." His insight highlights the importance of selecting proper equipment.

Underground Cable Pulling Socks are designed to streamline cable installations. They protect cables while allowing for a smooth, frictionless pull. These socks come in various sizes, accommodating different cable types. We often overlook how a simple tool can make a complex job easier. Some professionals underestimate their value, risking challenges during installation.

These socks not only provide protection but also contribute to faster installations. However, workers frequently forget to consider the implications of poor equipment selection. Reflecting on their use can lead to more efficient practices. Embracing tools like the Underground Cable Pulling Sock should not be optional but essential for success in the industry.

Underground cable pulling socks have become essential tools for installation efficiency. These specialized accessories simplify the pulling process of cables through conduits. Their lightweight design reduces friction, helping cables glide smoothly. This means fewer chances of damage during installation.

Using these socks can greatly decrease installation time. For instance, crews can pull multiple cables simultaneously without worry. The smooth surface minimizes the chances of tangling or snags. However, workers need to ensure proper sizing for optimal effectiveness. Socks that are too large may allow for slipping, which can hinder progress and efficiency.

Moreover, keeping the socks clean is crucial. Dirt and debris can compromise their performance. Some may overlook maintenance, leading to potential failures during critical installations. It’s important to regularly inspect and replace worn socks. Reflecting on these details can lead to better overall results in underground cable installations.

The durability of underground cable pulling socks largely depends on their material composition. High-quality polyester or nylon fibers are often chosen for their resistance to abrasion and wear. Industry reports indicate that socks made from such materials can withstand significant tensile pressures, often exceeding 600 pounds. These fibers help ensure that the pulling socks last longer and reduce the frequency of replacements, which can be costly.

On the flip side, not all materials perform equally well. Some cheaper alternatives may offer initial savings but fail under strain. A detailed study by a leading industry research group highlighted that lower-grade fabrics could fray or tear under moderate load conditions, leading to potential installation delays. Installers need to consider this impact when selecting cable pulling socks. Better-quality materials might come at a higher price, but they could ultimately improve efficiency and reduce downtime.

In terms of design, the way these socks are constructed also plays a role. Some designs feature reinforced stitching, which can further enhance durability. However, not every manufacturer prioritizes this feature. This inconsistency in quality can lead to confusion among users. A well-documented approach is to insist on specific materials and designs that have proven effective in field tests. It is crucial to evaluate the long-term performance of cable pulling socks to avoid the pitfalls of inadequate options.

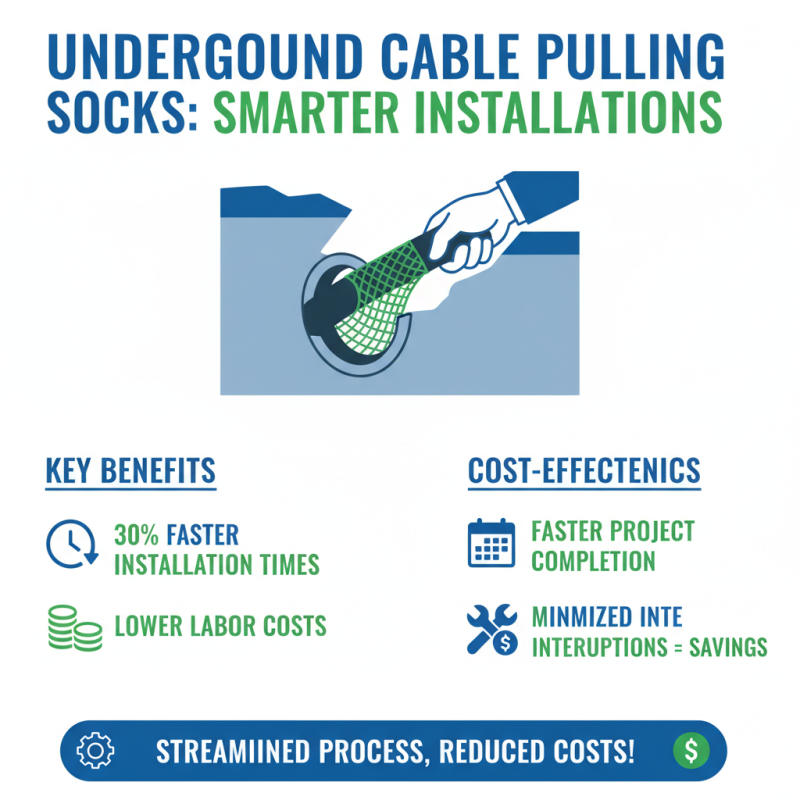

Using underground cable pulling socks can significantly improve installation efficiency. Proper techniques enhance their effectiveness. Start by selecting the right size of the sock to ensure a snug fit around the cable. A well-fitted sock minimizes friction, making it easier to pull cables through conduits. According to industry reports, using the correct sock can reduce pulling force by up to 30%. This result showcases both efficiency and cost-effectiveness in large scale installations.

When using these socks, it's crucial to pay attention to the pulling angle. A straight line minimizes wear on both the cable and the sock. However, improper angles can lead to damage. Many workers neglect the importance of this detail. Additionally, check for any debris in the conduit before starting the pull. Even small obstructions can increase resistance, complicating the process.

Remember to inspect the socks regularly for wear and tear. Frayed edges can lead to failures during installation. Incorporate these checks into your daily routine. Industry observations indicate that regular maintenance can extend the lifespan of tools and equipment by nearly 40%. Thus, using underground cable pulling socks with the right techniques not only boosts efficiency but also mitigates potential issues.

| Benefit | Description | Best Practices |

|---|---|---|

| Reduced Friction | Pulling socks help decrease friction between the cable and the conduit. | Ensure the sock is properly fitted to the cable diameter. |

| Protection of Cable | They provide a shield against potential damage during installation. | Use socks made from durable materials. |

| Enhanced Grip | The texture of the sock provides better grip for pulling. | Ensure socks are clean before fitting on cables. |

| Time Efficiency | Using socks can significantly speed up cable installation. | Plan pull routes carefully to minimize delays. |

| Less Labor Requirement | Fewer personnel may be needed to assist with pulls. | Training workers on sock use can optimize this benefit. |

| Compatibility | Suitable for various cable types and sizes. | Check compatibility before purchase. |

| Cost-Effective | Reduces costs associated with cable damage and rework. | Calculate long-term savings to justify initial costs. |

| Improved Safety | Helps prevent accidents caused by cable handling. | Adopt proper handling protocols when using socks. |

| Environmentally Friendly | Can be designed using sustainable materials. | Consider eco-friendly options when sourcing socks. |

| Reduced Wear and Tear | Minimizes damage to cables during long pulls. | Choose the correct length of sock for the job. |

When comparing cable pulling socks with traditional methods, significant advantages emerge. Traditional cable pulling often involves using ropes or chains, which can increase friction and lead to damage. A recent industry report noted that traditional methods could raise installation time by up to 30%. This delay is not ideal in a fast-paced construction environment where every hour counts.

In contrast, underground cable pulling socks minimize friction effectively. They streamline the process, allowing cables to glide smoothly through conduits. According to a study from a leading electrical engineering organization, the use of pulling socks can reduce installation times by nearly 25%. This efficiency translates to lower labor costs and improved project timelines.

Moreover, traditional methods can pose safety risks as workers struggle with heavy cables and equipment. Cable pulling socks are lighter and easier to handle. While some might argue socks do not fit every situation, their versatility is undeniable. Ironically, many still hesitate to adopt new technologies due to habit. Transitioning to modern solutions could enhance overall project efficiency significantly.

Underground cable pulling socks offer significant cost-effectiveness in installations. According to a recent industry report, using these socks can reduce installation times by nearly 30%. This leads to lower labor costs and faster project completion. The streamlined process minimizes interruptions, saving both time and money.

Many professionals report that proper installation practices using cable socks enhance efficiency. However, the initial investment in quality socks may be a concern for some. Over time, the durable nature of these socks can offset the upfront costs. In fact, studies show they can extend the lifespan of cables by preventing abrasion and wear.

Despite the clear benefits, challenges remain. Some may underestimate the importance of using the right size or type. Missteps like these can lead to installation delays, contradicting the goal of efficiency. Awareness of proper application methods is crucial. In many cases, training on these techniques could bridge the gap between expected and actual savings.