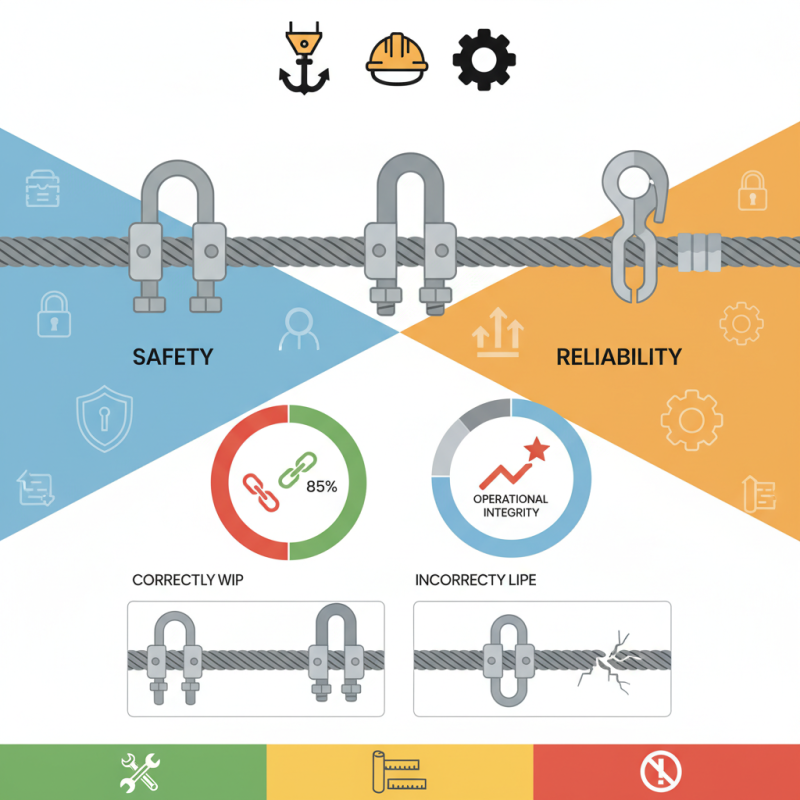

In heavy-duty applications, the choice of Wire Rope Clips and Cable Clamps is crucial. These components ensure safety and reliability in various industries, such as construction and maritime. According to a report by the International Wire Rope Association, nearly 15% of equipment failures are linked to improper use of wire rope components. Selecting the right clips can significantly reduce this risk.

Industry expert John Martinez, a renowned specialist in lifting equipment, states, "Using high-quality Wire Rope Clips and Cable Clamps is essential for maintaining operational integrity." This highlights the importance of using appropriate materials and designs in heavy-duty settings.

While many overlook the specifics, details matter. Different applications require varied specifications, and not all clips are suitable for every project. Inadequate attention may lead to failures and costly accidents. Therefore, investing time in understanding these essentials can be the difference between safety and disaster in heavy-duty work environments.

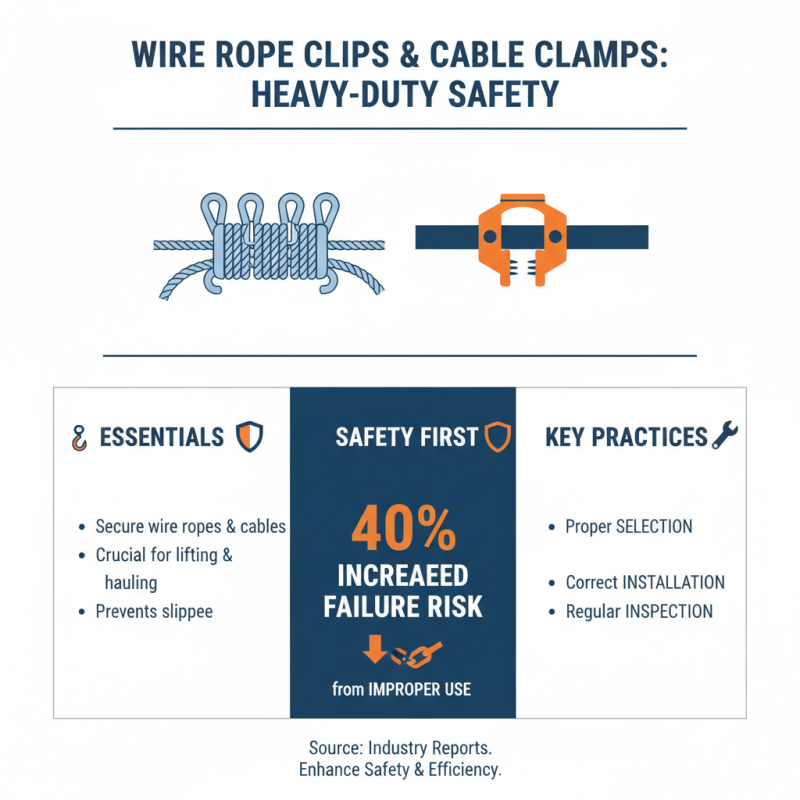

Wire rope clips and cable clamps are essential in heavy-duty applications. They secure wire ropes and cables during lifting or hauling operations. Understanding their importance can enhance safety and efficiency. According to industry reports, improper use of clips can lead to a 40% increase in failure rates. This statistic highlights the need for proper selection and installation.

Choosing the right wire rope clip is crucial for performance. For high-load situations, use clips made from steel. They offer greater durability and resistance to wear. Standard clips may not handle extreme conditions effectively. A study showed that using appropriate clamps can improve load stability by up to 30%. This enhances overall operational safety.

**Tip:** Always inspect clips regularly for wear and damage. Replace any compromised clips immediately. Also, remember that installation technique matters. A common mistake is using too few clips. This can lead to the rope slipping or failing. Always follow the manufacturer’s guidelines for clip spacing and torque specifications.

When selecting heavy-duty wire rope clips, consider key features that ensure safety and durability. Look for robust materials, like stainless steel or galvanized finishes, which resist corrosion. Proper construction is crucial. The best clips should have a substantial grip to hold the wire securely under tension. A design that allows for ease of installation can save time on the job.

Pay attention to the size and compatibility of the clips with your specific wire rope diameter. Verifying the specifications is vital. A mismatch can lead to failure. Inspect the clips for imperfections or defects before use. Even minor flaws can compromise their strength and performance.

Tips: Always read the manufacturer’s guidelines. Understand the load limits and stress ratings. Regularly inspect your wire rope clips after heavy use. Over time, wear can significantly affect their functionality. A proactive approach to maintenance can help avoid accidents or equipment failure.

Wire rope clips play a crucial role in heavy-duty applications. They serve to secure wire ropes and prevent slippage. Understanding the different types is essential for effective usage. The most common types include the U-bolt clip, the twin-saddle clip, and the swage clamp. Each has unique characteristics suited for various tasks.

U-bolt clips are popular for their ease of installation. However, they need proper tightening to ensure safety. The twin-saddle clip, on the other hand, offers a wider surface area. This design enhances gripping strength but may be bulkier in tight spaces. According to industry studies, improper application of wire rope clips can reduce their holding capacity by up to 40%. This highlights the critical need for correct installation procedures.

Swage clamps involve a more permanent solution. They require specialized equipment for installation. While effective, they can be challenging to remove if adjustments are needed. It’s vital to assess the application before choosing the type of clip. Some projects may benefit from a versatile approach, using a combination of different clips. An informed choice is key to maximizing performance and safety.

| Type | Material | Load Capacity (lbs) | Typical Application |

|---|---|---|---|

| U-Bolt Clip | Steel | 2,000 | Heavy lifting in construction |

| Double Saddle Clip | Stainless Steel | 3,500 | Marine applications |

| Cable Clamp | Aluminum | 1,500 | Electrical installations |

| Saddle Clip | Carbon Steel | 2,800 | Industrial lifting |

| Thimble Clip | Galvanized Steel | 4,000 | Rigging applications |

When working with heavy-duty applications, proper installation of wire rope clips and cable clamps is crucial. These components are designed to securely fasten and support wire ropes. However, many overlook the installation guidelines, which can lead to issues like slip or breakage. Start by ensuring you choose the right size of wire rope clips. An incorrectly sized clip can cause failures.

During installation, ensure the clips are placed correctly. The U-bolt should be positioned over the standing part of the wire rope. Tighten the nuts but avoid over-torquing, which can damage the wire. Many users tighten until it feels secure without realizing they might be compromising integrity. It's important to verify the alignment of the clips. Misalignment can lead to uneven wear on the wire rope.

Regular inspections are vital after installation. Look for any signs of wear or damage. If a clip is loose or corroded, it can compromise safety. Also, consider the environmental factors at play, such as moisture or chemicals that can degrade materials. Installation may seem straightforward, but ongoing maintenance and adjustments are key to longevity and safety. Reflect on how easy it is to neglect these small details.

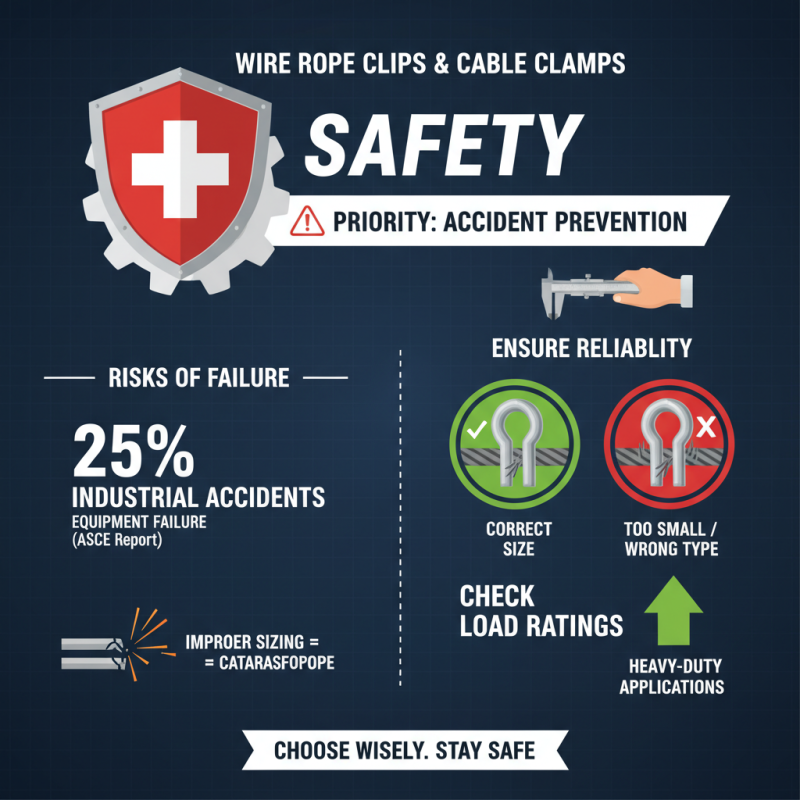

When utilizing wire rope clips and cable clamps, safety should be paramount. A report from the American Society of Civil Engineers links 25% of industrial accidents to equipment failure. This highlights the importance of choosing the right clips and clamps for heavy-duty applications. Many users overlook the load ratings. Clips that are too small or improperly sized can fail under stress, leading to dangerous situations.

One crucial tip involves regularly inspecting the wire rope clips and clamps. Visual checks can reveal signs of wear or corrosion. The Occupational Safety and Health Administration recommends inspections at least once a month for heavy-duty applications, especially in high-stress environments. Take the time to replace worn components. It might seem tedious, but it could prevent severe accidents.

Consider the environment where these clips and clamps will work. Moisture, chemicals, and extreme temperatures can affect performance. A surprising number of users do not account for these factors. Installations in harsher conditions often require additional protective measures. Use coatings or materials designed for durability. This proactive step can save time and resources in the long run.