In the world of electrical installations, a "Cable Installation Grip Net" plays a critical role. According to industry expert John Smith, "The grip net ensures safety and efficiency during the installation process." These specialized tools are designed to secure cables firmly, reducing the risk of slippage and ensuring a smooth workflow.

Cable Installation Grip Nets come in various sizes and designs, tailored to specific job requirements. They are used by professionals in construction and electrical wiring projects. Their unique design allows them to accommodate different types of cables, creating a versatile tool for workers. Despite their effectiveness, some users may overlook proper handling techniques, leading to potential hazards.

Understanding the significance of a Cable Installation Grip Net is vital. It enhances performance but requires attention and care. When misused, it can lead to complications on the job site. A small mistake could result in injuries or project delays. Therefore, continuous training and a focus on best practices are essential for success in cable installations.

A cable installation grip net is an essential tool in the telecommunications and electrical industries. This net is designed to hold and secure cables during installation. It is typically made from durable materials, ensuring it can withstand various conditions. The grip of the net helps to prevent any accidental slips or drops.

When using a cable installation grip net, it’s important to ensure it is properly attached. Misalignment can lead to issues during installation. The net should wrap around the cable snugly. If it feels loose, the grip won’t be effective. A tight grip ensures safety and stability while working at heights.

Workers often face challenges with knotting or tangling. It’s easy to overlook the simple steps for a smooth installation. Regular checks on the grip net's condition are essential. Worn-out nets can compromise the entire installation process. Proper training on how to use the net greatly improves efficiency. Taking the time to master this tool pays off in reliability.

A cable installation grip net is essential for securing and supporting cables during installation. Its design includes several key components that contribute to its effectiveness. The main elements are the gripping mechanism, the netting material, and the load distribution structure. These components work together to ensure that cables remain stable under various conditions.

The gripping mechanism typically features stainless steel or durable plastic. This material ensures a secure hold without damaging the cable. The netting is usually made of high-strength synthetic fibers. It provides flexibility while maintaining structural integrity. The load distribution structure helps to evenly spread weight across the grip net, which minimizes the risk of snags or breaks.

Tips for choosing a grip net: Always consider the weight and type of cables you will be using. A lighter grip net may not handle heavier loads effectively. It’s also beneficial to assess the environmental conditions. If you expect wet or extreme conditions, select materials that are resistant to corrosion and UV damage.

Remember, a well-designed grip net can increase efficiency during installation. However, improper use can lead to accidents. Regular inspections of the grip net are necessary to ensure safety. Look for signs of wear and tear, as these can compromise its functionality.

Cable installation grip nets find diverse applications across multiple industries. In telecommunications, these nets assist technicians in safely pulling cables through conduits. According to a 2022 report by the Telecommunications Industry Association, over 70% of companies rely on grip nets for efficiency and safety during installations. This spike in adoption reduces the time needed for cable deployment significantly.

In the construction sector, grip nets ensure that heavy cables are secured during hoisting. A 2023 construction safety report noted that improper cable handling accounts for 15% of workplace accidents. Grip nets help mitigate these risks, providing a more stable solution for transporting cables on-site. Meanwhile, the entertainment industry utilizes these nets for rigging tasks. They help hang lights and sound equipment, ensuring safety and organization during events.

However, challenges remain. Misuse of grip nets can lead to accidents. Training is vital, as incorrect usage can compromise their effectiveness. Awareness in various sectors about proper applications is still inconsistent. The industry must address these concerns to enhance safety and operational efficiency in cable installations.

| Industry | Application | Material Used | Benefits |

|---|---|---|---|

| Telecommunications | Cable installation for networks | Polyester | Increased grip and stability during installation |

| Utilities | High voltage cable installations | Steel wire | Enhanced safety and reduced risk of cable damage |

| Construction | Temporary support for heavy cables | Nylon | Lightweight and flexible handling |

| Marine | Underwater cable installations | Corrosion-resistant materials | Durability in harsh environments |

| Renewable Energy | Installation of wind turbine cables | Synthetic ropes | Safe management of dynamic loads |

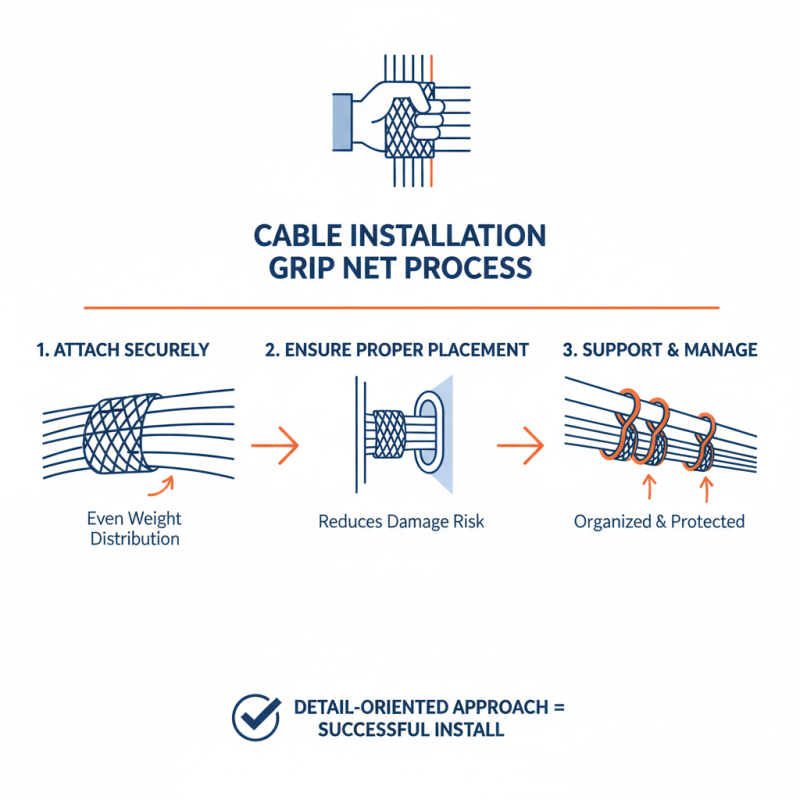

Using a cable installation grip net is a straightforward process, but attention to detail is critical. This tool helps manage and support cables during installation. Securely attaching the grip net to cables ensures even distribution of weight. Proper placement reduces the risk of damage to both cables and the installation area.

Before using a grip net, inspect it carefully. Look for any signs of wear or damage. These imperfections can lead to failures during installation. Adjust the grip net according to the specific cable size and type being used. This ensures an accurate fit and optimal support.

Tips: Always practice proper lifting techniques. Keep your back straight and bend your knees. Avoid twisting your body while lifting. Additionally, ensure that the workspace is clear of obstacles to prevent accidents. If you’re unsure, practicing with lighter cables can help build confidence before moving to heavier loads. Remember, a cautious approach can save you from potential setbacks during installation.

Cable installation grip nets are essential tools for safely handling cables during installation. They ensure secure and safe transport, minimizing the risk of accidents. However, proper maintenance and safety practices are crucial to their effectiveness. Regular inspections can help identify wear and tear, which may compromise safety.

When handling grip nets, always check for fraying or damage. The Occupational Safety and Health Administration (OSHA) states that nearly 20% of workplace injuries stem from improper handling of tools. Keeping nets clean can also prolong their lifespan. Avoid exposing them to chemicals that might degrade the materials.

Tip: Store grip nets in a dry, cool area to prevent deterioration. Avoid bending or twisting them excessively, as this can weaken their structure. It's vital to train all personnel on how to use them correctly. Remember that safety certifications for grip nets can vary. Regular updates and refreshers on proper usage can prevent accidents. Simplified guidelines can make a significant difference in a workplace's safety culture.