Marine rigging is a critical aspect of maritime operations, ensuring safety and efficiency in various nautical activities. Among the essential hardware used in rigging applications, the Dee Shackle stands out due to its versatility and strength. According to the American Boat and Yacht Council (ABYC), improper rigging can lead to significant safety hazards, with nearly 40% of maritime incidents attributed to equipment failure. The correct use of Dee Shackles not only enhances the durability of rigging systems but also minimizes the risks associated with structural overloads and line failures.

Furthermore, a study from the International Marine Contractors Association indicates that poor rigging practices contribute to 25% of accidents in marine environments. Understanding the proper application of Dee Shackles is therefore paramount for industry professionals. These robust connectors can reliably fasten sails, stabilize loads, and secure various marine components when utilized correctly. This article aims to provide a comprehensive guide on how to effectively use Dee Shackles while highlighting essential safety tips to ensure optimal performance and risk mitigation in marine rigging scenarios. By adhering to these best practices, sailors and marine operators can significantly reduce the likelihood of accidents and enhance operational efficiency.

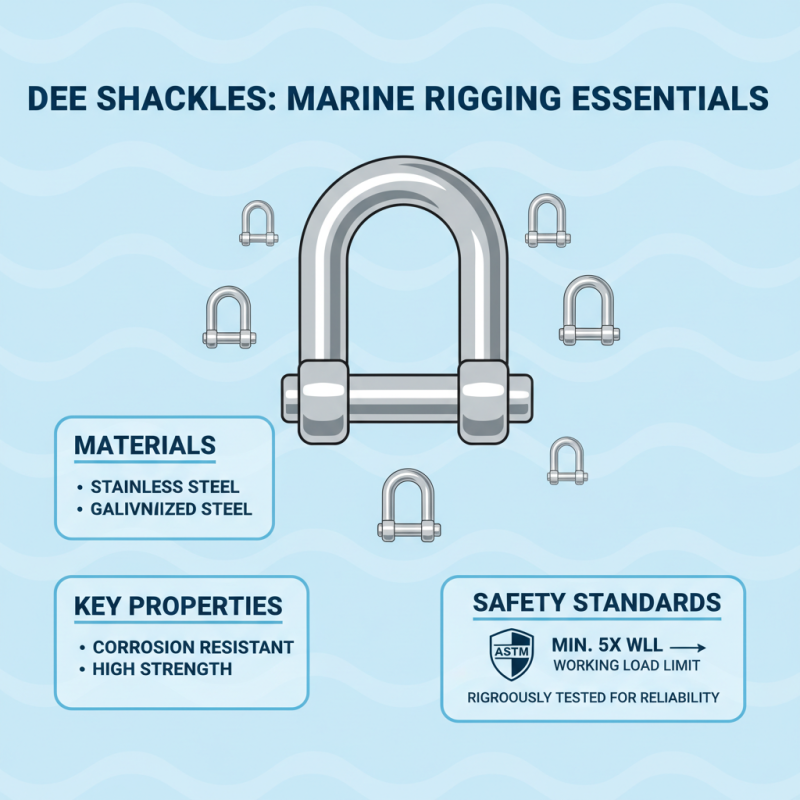

Dee shackles, essential components in marine rigging, come in various types and specifications designed to meet the rigorous demands of maritime environments. Generally made from high-strength materials such as stainless steel or galvanized steel, these shackles provide excellent corrosion resistance and strength-to-weight ratios, crucial for ensuring the safety of marine operations. Industry standards dictate that dee shackles should undergo rigorous testing to meet specific load ratings; according to the American Society of Testing and Materials (ASTM), a properly rated dee shackle must withstand a minimum of 5 times its working load limit (WLL) to ensure reliability and performance under stress.

When selecting a dee shackle, it is essential to consider not only the material and size but also the type of pin used. The two primary types of pins—screw pin and safety pin—offer varying levels of security and ease of use. A recent report from the International Marine Contractors Association (IMCA) indicates that improper use or selection of shackles accounts for over 25% of rigging failures in marine operations. Therefore, it's vital for marine professionals to be well-versed in choosing the correct type of dee shackle that meets the specific requirements of their applications, ensuring optimal safety and efficiency in marine rigging practices.

When using dee shackles in marine rigging, understanding key load ratings and safety standards is paramount for ensuring secure operations. Dee shackles are commonly rated based on their Working Load Limit (WLL), which indicates the maximum load they can safely support under normal use. It's essential to select shackles that exceed the anticipated load to provide an additional margin of safety. For instance, if a rigging operation requires a 1-ton capacity, choosing a shackle with a WLL of at least 1.5 tons is advisable. This practice minimizes the risk of failure and injury during marine activities.

Additionally, it's crucial to adhere to industry-standard safety guidelines such as those set forth by recognized safety organizations. These guidelines provide specifications for shackle design, material integrity, and periodic inspections. Regular checks for signs of wear, corrosion, or deformation can ensure that the shackles remain in optimal condition. Compliance with safety standards not only protects the equipment and personnel involved but also upholds industry best practices, which contribute to the overall effectiveness and reliability of marine operations.

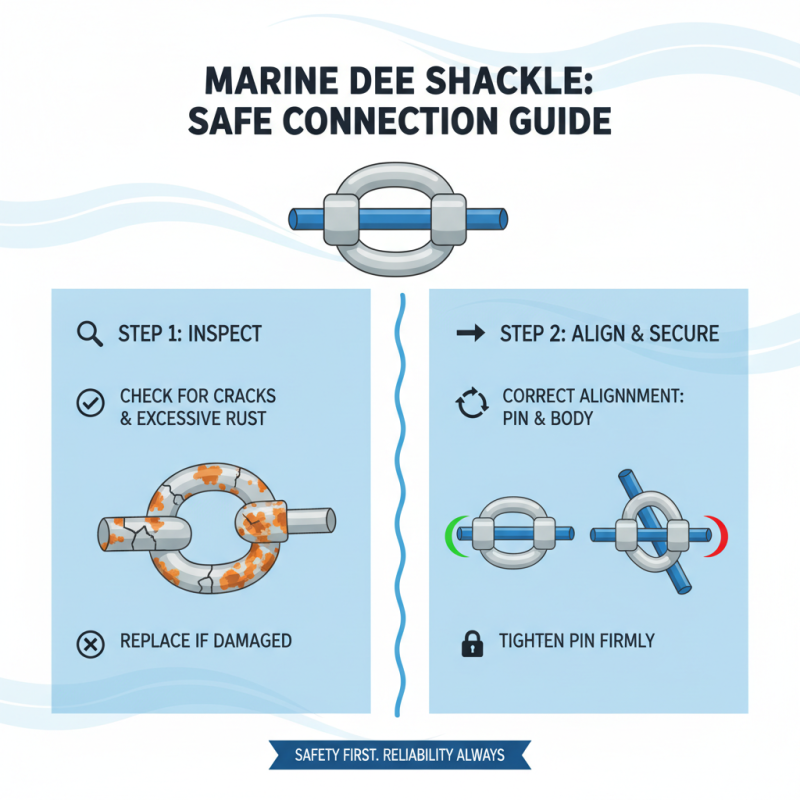

When it comes to marine rigging, ensuring the integrity and reliability of your equipment is paramount. Dee shackles, commonly used for connecting two elements, require regular inspection and maintenance to guarantee safe operation. One of the best practices involves performing visual checks for any signs of deformation, cracks, or corrosion. Inspect the pin and the body of the shackle rigorously, as even minor imperfections can compromise its load-bearing capacity.

Tips for maintaining dee shackles include keeping them clean and free from saltwater build-up, which can accelerate corrosion. A thorough wash with fresh water followed by a drying process should be standard practice after each use in a marine environment. Additionally, consider applying a protective coating designed for marine hardware to enhance durability. Always ensure shackles are properly secured when in use, and consider replacing them at the first sign of wear to uphold safety standards.

Regularly documenting inspection findings is another essential method to track the condition of your dee shackles over time. This can help identify trends in wear or damage that may require addressing. Implement a routine check schedule within your maintenance plan to ensure that these crucial components remain in optimal condition for any marine activity.

When working with Dee shackles in marine applications, it’s crucial to understand the proper techniques for connecting them to ensure safety and reliability. The first step is to always inspect the shackle prior to use. Look for any signs of wear or damage, such as cracks or excessive rust, which can significantly weaken the integrity of the shackle. Additionally, it is essential to align the shackle pin and the body correctly to prevent misalignment, which can lead to accidents under load.

Tips: Always use the right size Dee shackle for your application; an incorrectly sized shackle can compromise its load-bearing capacity. Moreover, never exceed the working load limit of the shackle, as this is a common cause of failure in marine rigging. Tighten the shackle pin securely but avoid overtightening, as this can cause thread damage and lead to difficulty in pin removal.

In marine environments, it's important to consider the influence of saltwater on metal components. Regular cleaning and maintenance will help prevent corrosion, prolonging the life of your Dee shackles. When connecting two chains or lines, ensure that the Dee shackle is secured with the pin oriented away from the load direction. This technique minimizes the risk of the pin loosening during use, enhancing safety during your maritime operations.

When utilizing dee shackles in marine rigging, it’s crucial to avoid common mistakes that can compromise safety and efficacy. One frequent error is failing to select the appropriate shackle size for the load. Underestimating the weight or stress acting on the shackle can lead to failure, resulting in dangerous situations. Always ensure that the shackle’s working load limit is suitable for the intended application, taking into account dynamic loads that may arise during marine operations.

Another common pitfall is neglecting proper inspection and maintenance of the shackles. Over time, these components can suffer from wear and corrosion, which significantly reduces their strength. Regularly checking for signs of damage—such as deformation, rust, or pitting—is essential to maintain safety standards.

Furthermore, an often-overlooked mistake is the incorrect orientation of the shackle pin. It should always be threaded downward, preventing it from loosening due to vibration or movement. Adhering to these simple precautions will enhance both safety and the overall integrity of your marine rigging setup.