In the world of heavy lifting and load management, the importance of precise and reliable equipment cannot be overstated. Among the various tools available, Dee Shackles have emerged as essential components for ensuring safety and efficacy in lifting operations. According to a recent report by the International Lifting Equipment Engineers Association (ILEEA), improper equipment can lead to over 40% of workplace accidents in the construction and logistics sectors, emphasizing the need for dependable solutions like Dee Shackles that comply with stringent safety standards.

Industry expert and noted mechanical engineer Dr. James Holloway states, “In an industry where every detail matters, the role of Dee Shackles in load management cannot be underestimated. They not only enhance the structural integrity of lifts but also ensure a more controlled and balanced load distribution.” His insights reflect a broader consensus among professionals, underscoring the significance of using high-quality Dee Shackles to minimize risks associated with load handling. By incorporating these durable shackles into their operations, industries can better protect their workforce, assets, and project timelines, thereby fostering a culture of safety and efficiency.

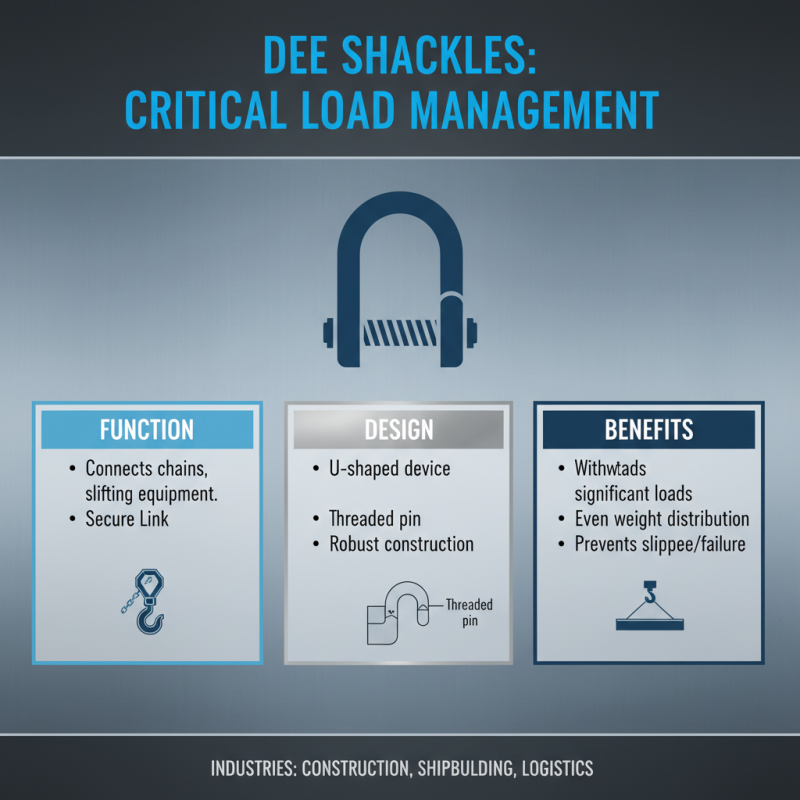

Dee shackles play a pivotal role in load management, serving as critical connectors in rigging and lifting applications. Defined as U-shaped devices with a threaded pin, dee shackles are designed to securely link various components, including chains, slings, and lifting equipment. Their robust construction ensures that they can withstand significant loads, making them an essential tool in industries such as construction, shipbuilding, and logistics. The ability of dee shackles to distribute weight evenly aids in preventing slippage and reduces the risk of equipment failure during lifting operations.

When using dee shackles, it's crucial to consider the load rating and ensure it meets or exceeds the load being lifted. Additionally, inspect the shackles regularly for any signs of wear or damage, as even minor defects can lead to catastrophic failures.

Tips for effective load management include always aligning the dee shackle properly with the load to maintain optimal force distribution and ensuring the pin is fully threaded to avoid accidental disengagement. Moreover, it's advisable to avoid side loading the shackles, as this can compromise their integrity and lead to potential hazards. Ultimately, following these guidelines can enhance safety and efficiency in any lifting operation.

Load management is crucial across various industries, ensuring safety, efficiency, and cost-effectiveness in operations. In construction, for instance, managing the weight of materials and equipment is essential to prevent accidents and structural failures. Proper load distribution helps in maximizing the lifespan of machinery and reduces wear and tear, ultimately leading to significant savings. By implementing effective load management strategies, construction companies can enhance their operational productivity while safeguarding their workforce.

In logistics and transportation, load management plays a pivotal role in optimizing cargo space and improving fuel efficiency. Properly managed loads prevent overloading, which can lead to regulatory issues and increased operational risks. Additionally, appropriate load distribution ensures that vehicles perform optimally, enhancing delivery times and reducing costs. This attention to load management not only boosts efficiency but also supports sustainability efforts by minimizing the environmental impact of transportation activities. Overall, effective load management is integral to operational success across various sectors.

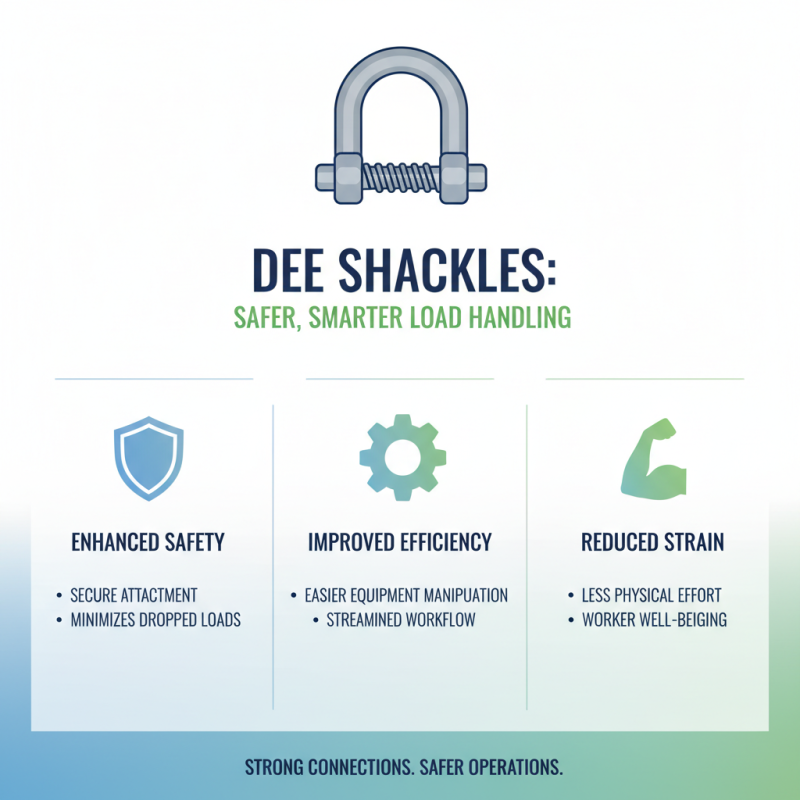

Dee shackles play a critical role in enhancing safety and efficiency in load handling operations. Their design integrates a sturdy structure that allows for secure attachment of various lifting equipment and load attachments. This secure connection is vital as it minimizes the risk of dropped loads, ensuring that materials are safely moved without incident. Furthermore, the smooth operation of dee shackles facilitates easier manipulation of heavy equipment, significantly reducing the physical strain on workers and improving workflow efficiency.

In addition to promoting safety, dee shackles are essential in optimizing load distribution. Their capacity to handle different load shapes and sizes means they can be used in a variety of lifting scenarios, from construction to heavy manufacturing. This versatility allows operators to align the center of gravity effectively, which is crucial in maintaining balance during transfers. Consequently, the risk of accidents due to load imbalance is significantly lowered, contributing to a safer working environment. Overall, the use of dee shackles not only streamlines load handling processes but also establishes a culture of safety that is paramount in any operational setting.

Dee shackles have emerged as a critical component in effective load management, offering unique advantages over traditional tools. In a recent industry report by the International Association of Load Management, it was noted that the use of dee shackles can increase load distribution efficiency by up to 25% compared to standard pin shackles. This improved efficiency is due to their design, which allows for a more balanced load and reduced risk of slippage, making them ideal for dynamic lifting environments.

When comparing dee shackles to other load management tools such as turnbuckles and eye bolts, several key differences surface. A study published in the Journal of Lifting Equipment reveals that dee shackles provide superior strength ratings, often rated to handle loads exceeding 8 tonnes for standard sizes, while turnbuckles typically accommodate lower loads. Furthermore, the ease of attachment and detachment of dee shackles enhances operational efficiency, reducing the risk of accidents and improving workflow. As the construction and logistics industries continue to prioritize safety and performance, the adoption of dee shackles as a primary tool for load management becomes increasingly justified.

Dee shackles play a vital role in load management, acting as key components in lifting and rigging operations. To ensure safety and efficiency, industry best practices should be continuously applied. One important aspect is choosing the right size and type of dee shackle, as improper selection can lead to equipment failure or accidents. According to recent industry reports, about 30% of lifting incidents are attributed to incorrect rigging practices, making it essential to adhere to proper usage guidelines.

**Tips:** Always refer to the manufacturer's specifications to determine the correct Working Load Limit (WLL) for dee shackles, and consider using a safety factor of at least 5:1 for critical lifts. Regular inspection of shackles for wear and damage is also crucial; even minor deformations can significantly affect their load-bearing capacity.

In addition to selection and maintenance, proper attachment methods are essential. Dee shackles should always be aligned correctly to reduce the risk of bending or twisting under load. A recent survey indicated that misalignment accounts for approximately 20% of rigging-related failures. Training personnel on proper techniques and routinely practicing load management scenarios can help mitigate these risks and enhance overall operational safety.

**Tips:** Implement a routine training program to keep team members informed about the best practices in using dee shackles. Consider utilizing checklists before each lift to ensure all safety protocols are followed, reinforcing a culture of safety in load management.

| Load Type | Load Weight (lbs) | Dee Shackle Type | Working Load Limit (WLL) (lbs) | Best Practice |

|---|---|---|---|---|

| Steel Pipes | 1500 | Grade 80 | 3100 | Use with a suitable sling |

| Construction Materials | 2000 | Grade 100 | 4200 | Inspect for wear before use |

| Shipping Crates | 1000 | Grade 70 | 3200 | Ensure load is balanced |

| Automotive Parts | 800 | Grade 80 | 3400 | Avoid shock loading |