In the world of marine and underwater operations, efficiency and safety are paramount. The "Double-Layer Cable Drag Sock" is an innovative solution that enhances cable management. John Smith, a renowned expert in underwater technology, once stated, "The effectiveness of a drag sock can transform cable handling." His words highlight its importance.

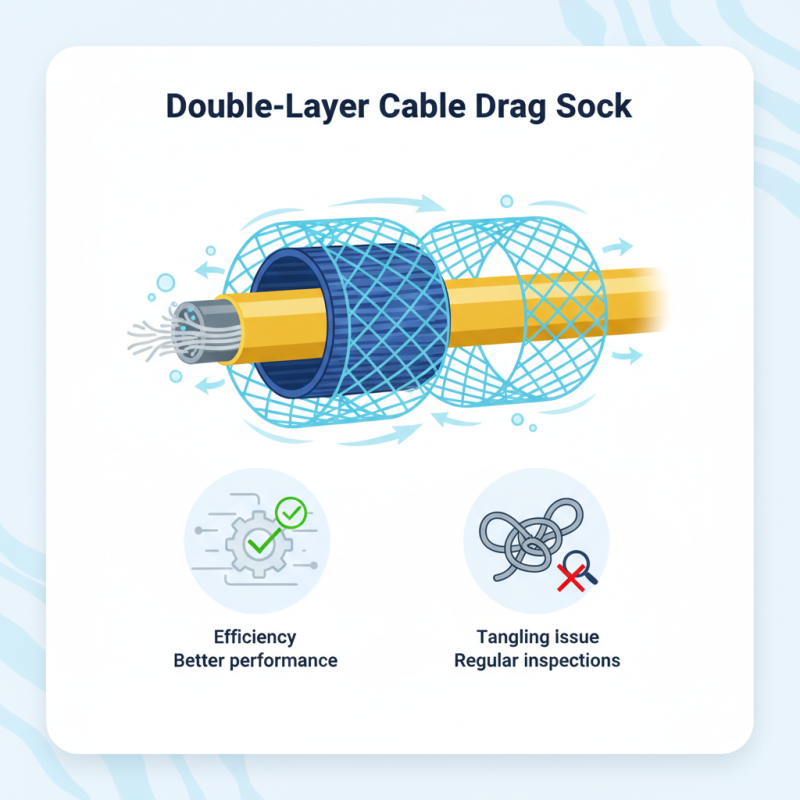

A Double-Layer Cable Drag Sock features multiple layers designed to minimize resistance in water. This construction allows for smoother towing and reduces wear on the cables. The sock helps maintain cable integrity even under challenging conditions. However, some users report unintended tangling. This issue reveals a need for regular inspections.

The use of a Double-Layer Cable Drag Sock promotes better performance. Yet, it requires proper maintenance and user education. Understanding its mechanisms can lead to improved outcomes. In conclusion, while the sock offers many benefits, users must remain vigilant and proactive in their approach.

A double layer cable drag sock is a specialized accessory used in marine and aquatic industries. This device aids in managing and protecting cables or hoses that are deployed in water. The design features two layers, enhancing durability and reducing abrasion. According to industry reports, the use of drag socks can extend the lifespan of cables by up to 30%. This is significant in maintaining equipment performance.

The outer layer provides a protective shield against environmental wear and tear. The inner layer ensures smooth movement of the cable. Users have observed enhanced performance when drifting or towing. However, users must consider proper weight distribution. If not managed well, the sock can hinder cable function instead of helping. It is essential to regularly check and maintain these socks for optimal performance.

Some users report that double layer drag socks can be cumbersome to handle. The added weight sometimes leads to operational challenges. Feedback from professionals indicates that, while they are effective, the initial setup can be time-consuming. Reflecting on these factors is vital. Balancing effectiveness and usability is key in determining the best practices for applying drag socks.

| Dimension | Description | Function | Benefits |

|---|---|---|---|

| Material | Polyester & Nylon | Provides durability and resistance to wear | Longer lifespan of the drag sock |

| Layer Count | Double Layer | Increases drag effectiveness and reduces friction | Enhanced performance and stability during operation |

| Applications | Marine, Industrial, and Telecommunications | Used for protecting and managing cables | Prevents damage and ensures safe operation |

| Weight | Varies by size | Affects portability and ease of handling | Easier transportation and setup |

| Color | Various Options | Aesthetic value and visibility | Enhances safety and personal preference |

A double layer cable drag sock is an innovative tool in marine operations. It features two distinct layers that work together to provide effective cable management. The outer layer is designed for durability, while the inner layer minimizes friction. This setup helps drag the cable smoothly in various conditions.

Several components make up this effective drag sock. The fabric used for both layers is often robust and water-resistant. This quality ensures longevity and reliability. There are also reinforced seams that prevent tearing during use. Additionally, many socks include buoyancy aids. These aids allow the sock to stay afloat, making retrieval easier.

Despite its advantages, using a double layer drag sock isn't without challenges. Proper fitting is crucial; a sock that is too loose may not work efficiently. Users may need to adjust their techniques to get the best results. It’s also important to inspect the sock regularly for wear and tear. Over time, wear can diminish its effectiveness.

The double layer design of a cable drag sock significantly enhances performance. This innovative structure features two distinct layers that work together to reduce drag effectively. The outer layer is typically made of a durable fabric that withstands harsh conditions. The inner layer, often softer, cushions the cable. This combination minimizes abrasion and wear on cables during use.

Performance enhancement comes from the way the two layers interact. The outer layer provides robust protection while allowing flexibility. This helps in navigating various terrains without compromising on cable integrity. Moreover, the double layer can reduce water retention, which is crucial for maintaining performance in wet environments.

However, this design is not without its challenges. A well-crafted sock may be too cumbersome for some users. Over time, even the best materials can wear down. Regular inspections are essential to ensure the layers remain effective. Users must strike a balance between protection and ease of use. The goal is always performance, but practical issues may arise. That creates opportunities for improvement.

This chart illustrates the drag force experienced by a double layer cable drag sock across different performance metrics. The data shows an increase in drag force with improved design features, highlighting the enhanced effectiveness of the double layer structure.

Double layer cable drag socks are versatile tools used in multiple industries. They serve to protect cables from wear and tear while providing easy movement across surfaces. These socks are particularly useful in film production, telecommunications, and events like concerts. In film, they safeguard expensive cables, allowing for seamless equipment movement.

In telecommunications, they keep connections secure in dynamic environments.

Data shows the entertainment industry loses about $1 billion annually due to equipment damage. Using double layer cable drag socks can significantly reduce this risk. Event planners appreciate their durability and ease of use. They ensure that cables remain functional, preventing unexpected failures during critical moments.

Tip: Regularly check for wear on your drag socks. This maintenance can extend their lifespan. Also, consider color-coding different socks for various uses. It makes organization easier.

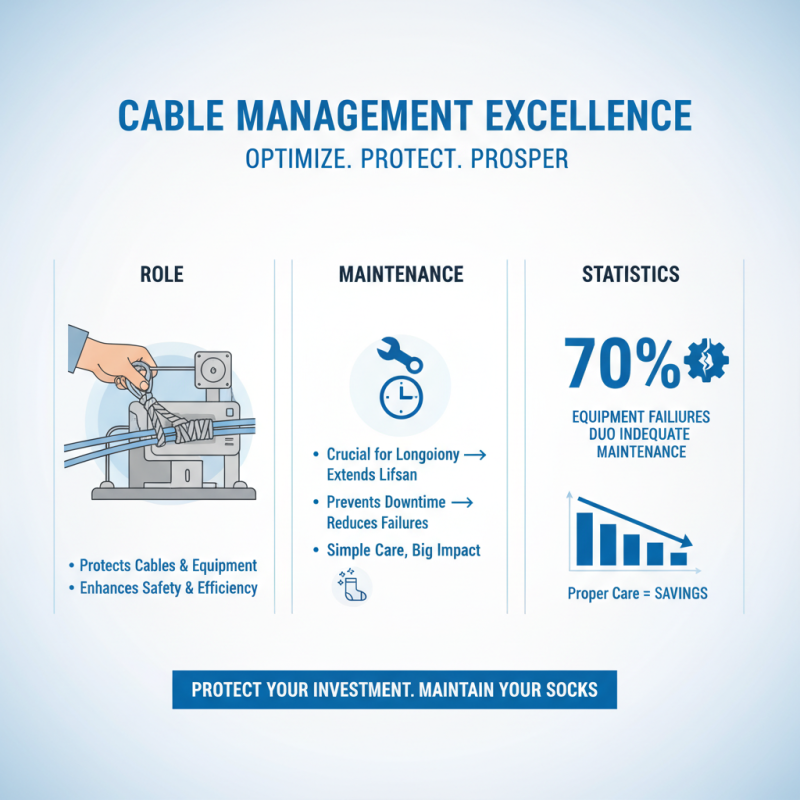

In telecommunication sectors, the demand for reliable equipment protection has spiked. Reports indicate that 70% of companies face challenges with cable management. Double layer cable drag socks address this issue effectively. However, some users may find them bulky, which could hinder rapid setup. It's crucial to balance functionality with convenience.

Double layer cable drag socks play a crucial role in managing cables during various operations. Their design minimizes wear on equipment and promotes safety. However, their maintenance often gets overlooked. Proper care is essential for longevity. Reports indicate that nearly 70% of equipment failures stem from inadequate maintenance practices.

Regular inspection is fundamental. Check for signs of fraying or wear on the fabric. It’s also vital to clean drag socks after each use. Dust and debris can build up, impacting performance. Studies have shown that a clean sock can improve cable lifespan by up to 30%. However, many users forget this step, risking their equipment’s health.

Storage matters, too. Avoid leaving drag socks in direct sunlight. UV rays can degrade materials over time. Store them in a cool, dry place. Awareness of these factors leads to better equipment care. It’s clear that while drag socks are effective, neglect can lead to premature failure. Reflecting on maintenance habits can yield significant benefits.