In the ever-evolving landscape of construction and electrical installation, the efficient use of resources is paramount, particularly when it comes to cable management. Research from the Electrical Contractors Association (ECA) indicates that poor cable handling can lead to significant delays, making it critical for professionals to adopt innovative solutions. One such solution is the use of Cable Pulling Mesh, which has been shown to reduce installation time by up to 30%, according to a recent industry survey. This versatile tool not only enhances the speed of cable pulling but also minimizes the risk of damage to cables during installation. As the demand for more reliable and efficient electrical systems increases, leveraging Cable Pulling Mesh can substantially improve project outcomes and align with best practices in modern electrical work.

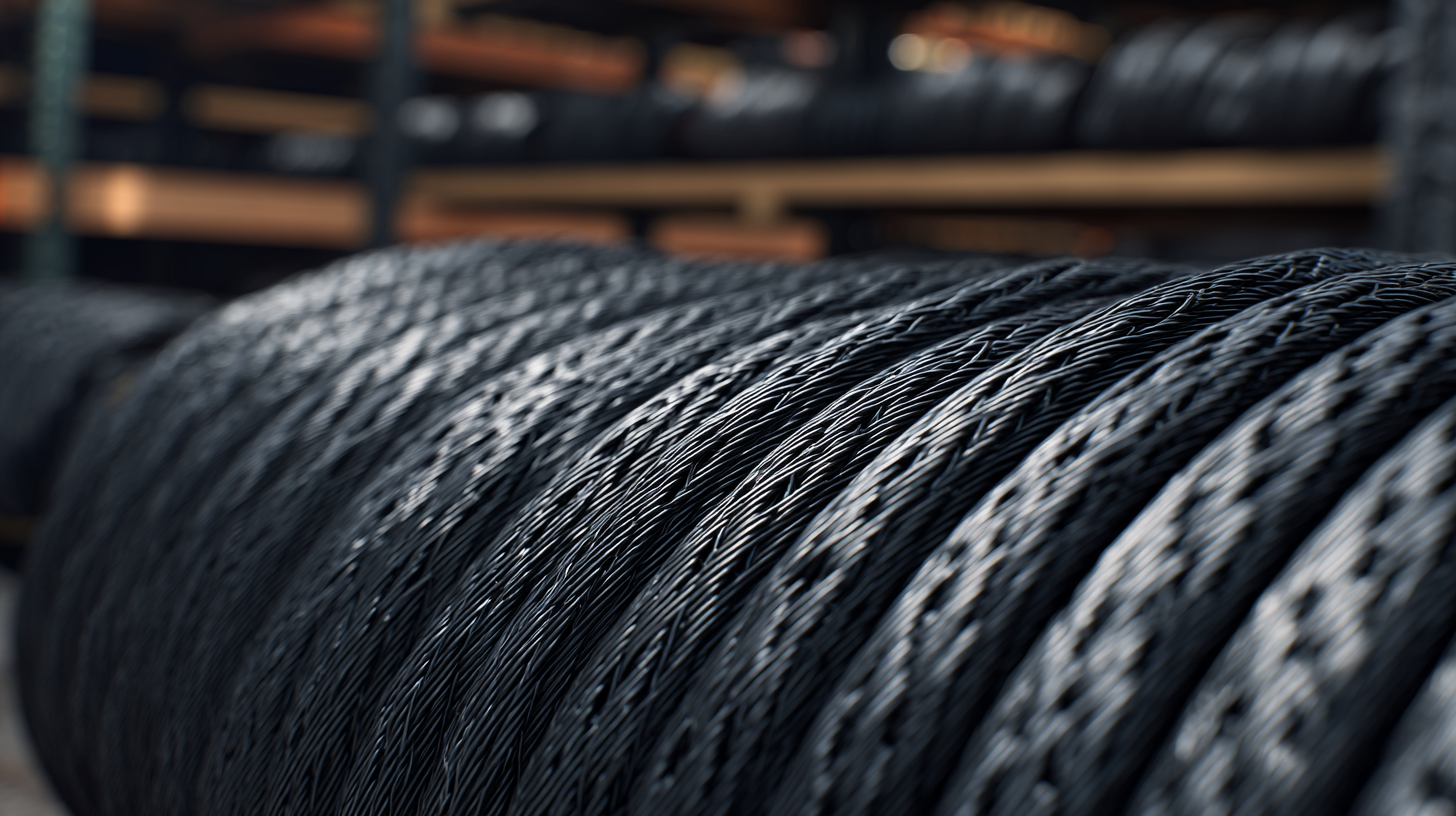

Cable pulling mesh is an essential tool in the realm of electrical installations, providing both efficiency and safety during cable management tasks. This innovative product is designed to facilitate the pulling of multiple cables through conduits, ducts, and tight spaces. Understanding the basics of cable pulling mesh involves recognizing its construction—typically composed of durable yet flexible materials like nylon or polyester. These materials ensure that the mesh can withstand the rigors of heavy-duty use while helping to prevent tangling and snagging of the cables.

The applications of cable pulling mesh are diverse, spanning various industries, including telecommunications, construction, and electrical engineering. In telecommunications, for instance, the mesh allows for the quick installation of fiber optic cables, ensuring that projects remain on schedule. In construction, cable pulling mesh helps streamline the wiring process in commercial buildings, where numerous cables need to be navigated through complex pathways. By utilizing cable pulling mesh effectively, project managers and technicians can achieve significant time savings and reduce the risk of damage to the cables themselves, leading to safer and more efficient project outcomes.

This chart illustrates the percentage of various applications for cable pulling mesh, highlighting its importance in different sectors.

When selecting cable pulling mesh for your next project, it’s crucial to consider several key factors to ensure efficiency and effectiveness. First, evaluate the material of the mesh. High-quality meshes are typically made of durable synthetic materials that can withstand tension and resist wear and tear during pulling operations. Choose a mesh that is compatible with the type of cables you’re using to avoid damage.

Tips: Always check for load specifications provided by the manufacturer, as using a mesh that can’t handle the weight of your cables could lead to mishaps. Additionally, consider the mesh's width and length; a wider mesh can accommodate more cables, while adequate length ensures you cover the necessary distance needed for your installation.

Another important factor is the mesh’s flexibility. A flexible mesh allows for easier maneuvering around bends and corners in tight spaces. This flexibility can save time and resources during your project.

Tips: When in doubt, opt for a one-size-fits-all approach with adjustable features. This will help you adapt to unexpected changes in cable sizes or installation layouts, ultimately enhancing your workflow and productivity.

When embarking on a project that requires cable installation, utilizing cable pulling mesh can significantly enhance efficiency and safety. According to the National Electrical Contractors Association (NECA), improper cable installation can lead to increased project times and potential rework costs, emphasizing the importance of effective techniques.

To set up cable pulling mesh correctly, start by assessing the environment where the installation will take place. Ensure the work area is clear and accessible; clutter can impede the pulling process and create safety hazards.

Next, the installation process begins with measuring the distance and identifying anchoring points. This data is critical, as improper measurements can result in excess strain on cables and the pulling mesh. The industry standard recommends a radius of at least ten times the cable’s diameter for bends to prevent damage during installation, according to a report by the Cable and Connectivity Industry Association (CCIA).

Once your parameters are set, secure the pulling mesh at the designated points, making sure to account for any potential obstacles. This meticulous approach not only streamlines the pulling process but also aligns with best practices that enhance the durability and longevity of the cables used in the project.

When it comes to maintaining and storing cable pulling mesh, proper care is essential to ensure its longevity and effectiveness in your projects. The first step in maintenance is to inspect the mesh regularly for any signs of wear or damage. Look for frayed edges or weakened areas that could compromise its performance. If you notice any issues, it's best to replace the mesh before it fails during a job.

**Tips:** Always clean the mesh after use to remove dirt, debris, and other contaminants. You can use mild soap and water, followed by thorough drying to avoid mold and mildew build-up. Additionally, when storing, avoid folding the mesh tightly; instead, roll it gently to prevent creases that could weaken its structure.

Storing cable pulling mesh correctly can extend its lifespan dramatically. Keep it in a dry, cool place away from direct sunlight to prevent degradation from UV exposure. Using a designated storage container can help keep it safe from tangling and potential damage.

**Tips:** Label your storage containers for easy access, ensuring that you know exactly where each mesh type is stored. Consider organizing your mesh by size or type to streamline your workflow for upcoming projects.

When utilizing cable pulling mesh in your next project, avoiding common mistakes is crucial for efficiency and safety. One prevalent mistake is underestimating the importance of proper measurement and planning. It's essential to evaluate the cable's length and the mesh's load capacity before starting. Failing to do so can lead to inadequate support during the pulling process, potentially resulting in cable snags or breakage.

Another common error is neglecting to check for wear and tear on the cable pulling mesh itself. Just like any tool, worn-out mesh can compromise the integrity of the entire operation. Always inspect the mesh for frays or damage before use. Additionally, improper technique is a significant pitfall; rushing the pulling process can lead to tangles and kinks. Instead, take your time to pull the cables smoothly, ensuring that everything is aligned properly. By being mindful of these mistakes, you can enhance your project’s success and safety when using cable pulling mesh.

| Mistake | Description | Solution |

|---|---|---|

| Improper Sizing | Using a cable pulling mesh that is too small or too large for the cables can lead to complications during installation. | Always measure your cables and select the appropriate mesh size before beginning. |

| Neglecting Load Capacity | Exceeding the mesh's load capacity can cause breakage or damage to cables. | Check the manufacturer's specifications for load limits and ensure you are within those limits. |

| Poor Installation Technique | Improper installation methods can stress the cables and pulling mesh, leading to failures. | Follow best practices for installation, including gradual pulling and using appropriate tools. |

| Lack of Communication | Failure to communicate with the team can lead to misalignment and mistakes. | Ensure clear communication among all team members involved in the cable installation process. |

| Ignoring Safety Protocols | Neglecting safety procedures can put workers at risk during installation. | Always adhere to safety guidelines and wear appropriate protective gear. |