When it comes to selecting the perfect bolt type shackle, expert insights can be invaluable. John Carter, a noted specialist in the rigging industry, once stated, “Choosing the right bolt type shackle can make or break your rigging project.” With so many options available, navigating this decision can feel overwhelming.

Various factors come into play when selecting a bolt type shackle. Load capacity, material, and configuration are crucial. Each project may have unique needs, and matching the shackle to those demands is essential. A misstep here could lead to safety risks, inefficiency, and financial waste.

Even experienced professionals sometimes overlook vital details. For instance, they might choose a shackle that seems adequate but fails under specific conditions. It's critical to ask questions and assess every option. The right bolt type shackle is not just a tool; it's a solution tailored to your requirements, ensuring safety and reliability in your operations.

When selecting a bolt type shackle, understanding its specifications is crucial. Different types serve various applications. For instance, bow shackles are often used in lifting tasks due to their wide body and load distribution. Their design can handle dynamic loads better, which is vital in construction environments where weight limits are a concern. Industry reports indicate that improper use of shackles can lead to accidents, emphasizing the need for proper selection.

Pin type is another common option. The screw pin shackle allows for easy removal and reassembly. However, it is less secure against accidental release. According to a recent industry analysis, approximately 30% of lifting injuries result from equipment failure, including shackle misuse. These numbers call for careful consideration before making a choice.

Checking the load rating is non-negotiable. Each shackle type has specified limits for safe usage. Bow shackles might support over 40 tons, while smaller D shackles may only manage around 10 tons. Knowing your working environment and load characteristics can greatly reduce risks. Ignoring these factors might lead to costly mistakes. Proper education on specifications can be the difference between safety and disaster.

When selecting a shackle, load ratings are crucial. This is the first filter for determining your choice. Inspect the manufacturer's specifications. Ensure the shackle can handle the maximum load you plan to use. Remember, safety is paramount. A shackle rated below your load could fail when you least expect it.

For practical applications, consider the working load limit (WLL). This limit is your best guide. Make sure it exceeds your maximum load by a safe margin. A common rule is to select a shackle with a WLL of at least double your load. This adds a buffer for unexpected forces.

Think about the environment too. Will your shackle face corrosion or extreme temperatures? These factors affect performance. Regular inspection is key. It’s easy to overlook wear and tear. Reflect on past experiences and adapt. This mindful approach will enhance safety and longevity in your projects.

When choosing a bolt type shackle, material plays a crucial role. The most common materials are stainless steel, carbon steel, and aluminum. Each material offers distinct advantages and disadvantages. For example, stainless steel resists corrosion well, making it suitable for marine environments. However, it can be heavier and more expensive.

Carbon steel is strong and cost-effective. It's ideal for general lifting purposes. Yet, carbon steel lacks corrosion resistance. This can lead to rust and reduced lifespan when exposed to moisture. Aluminum, on the other hand, is lightweight and resistant to corrosion. But it has lower strength than steel options.

Many users overlook the importance of material in their decision-making. A shiny, appealing look might catch the eye, but performance matters more. The right choice depends on your specific application. Always consider the environment where the shackle will be used. Testing different materials in real scenarios helps identify the best option. Balancing weight, strength, and cost is often challenging. Reflect on your needs carefully before making a decision.

| Shackle Type | Material | Working Load Limit (WLL) | Corrosion Resistance | Application |

|---|---|---|---|---|

| Bow Shackle | Steel | 4,000 lbs | Moderate | General Lifting |

| D Shackle | Stainless Steel | 6,000 lbs | High | Marine Use |

| Anchor Shackle | Galvanized Steel | 8,000 lbs | Moderate | Industrial Rigging |

| Lightweight Shackle | Aluminum | 2,000 lbs | Low | Outdoor Activities |

| Reeving Shackle | Carbon Steel | 10,000 lbs | Low | Construction |

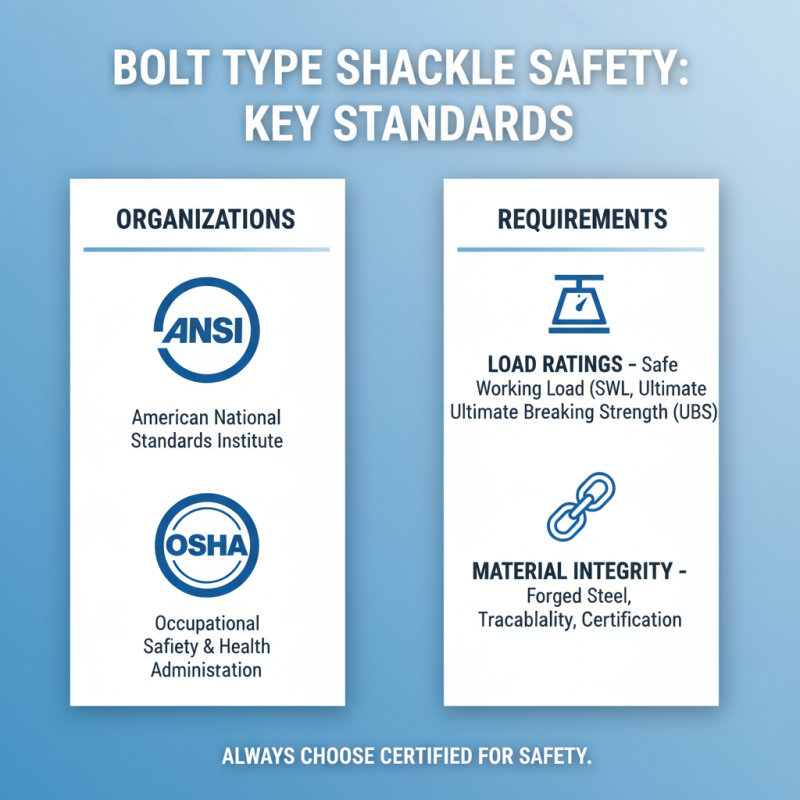

When selecting bolt type shackles, understanding safety standards and certifications is vital. Various organizations set guidelines for these components. For instance, the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) outline specific requirements. Their specifications often emphasize load ratings and material integrity.

The European standard EN 13889 also plays a significant role. It classifies shackles by working load limits. These limits are crucial when assessing shackle performance under stress. A report from the International Organization for Standardization (ISO) highlights that failure to comply with safety standards can lead to catastrophic accidents. It claims that 65% of accidents stem from equipment malfunction due to inadequate safety measures.

Ensure that shackles are certified and marked. Look for traceability features on the product. If you find that a shackle lacks proper documentation, reconsider your choice. Remember, high-quality safety ratings provide peace of mind and work efficiency. Assess your operational environment. Craft your selections based on specific needs. This way, you can mitigate risk while maximizing safety. The burden of safety should not be overlooked.

When choosing the right bolt type shackle, installation and maintenance play a crucial role in ensuring their longevity. Proper installation is vital. Always verify that the shackle is the correct size and type for your application. If it’s too loose or tight, issues can arise. Check the pin alignment during installation. This can prevent unnecessary wear and tear over time. Furthermore, make sure the shackle is positioned correctly to minimize stress during use.

Regular maintenance is equally important. Inspect the shackle for signs of wear or damage periodically. Look for rust, cracks, or bent components. These issues can compromise safety. Clean the shackle with mild soap and water. Avoid harsh chemicals that may degrade the material. Lubricate moving parts to ensure smooth operation. Failing to do so can lead to rust formation. Rugged environments often accelerate wear and tear.

Lastly, consider your operating environment. Outdoors, the elements can take a toll. For example, exposure to saltwater can cause corrosion. If your shackle isn’t designed for such conditions, it won't last long. Make decisions based on your specific needs. Reflect on potential misuse during installation or operation. A little attention to detail goes a long way in extending the life of your shackle.