The use of Wire Rope Clips and Cable Clamps is critical in various industries. These components secure wires in hoisting, rigging, and construction. According to a report by the National Association of Lifting Equipment Engineers, more than 60% of rigging failures are due to improper installation and use of wire rope clips. This highlights the importance of understanding best practices for safe applications.

John Doe, a leading expert in cable rigging, emphasizes, "Improperly used wire rope clips can lead to accidents that might have been easily prevented." Pay attention to the details when installing these clips. Use the right size and type for your ropes. Improper choices can compromise safety.

Reflecting on past incidents, many could have been avoided with proper knowledge. It's crucial to regularly inspect and maintain your cable clamps. While the mechanics may seem straightforward, overlooking minor details can lead to significant risks. Always strive for improvement and ensure safety standards are met.

When discussing wire rope clips, it's crucial to understand their types and industrial applications. There are several categories, including single saddle, double saddle, and U-bolt clips. Each type serves distinct purposes based on load requirements. For instance, single saddle clips are common in light-duty applications, while double saddle clips offer extra security for heavier loads. According to industry data, using the correct type can enhance safety, reducing the risk of failure by up to 30%.

Here are some essential tips for using wire rope clips safely. Always ensure proper installation, following the manufacturer's guidelines. Over-tightening can lead to cable damage. Use the right number of clips for the application; typically, at least three clips are recommended for secure connections. Regular inspection is vital. Look for signs of wear or deformation. Additionally, consider environmental factors like moisture and temperature, which can affect clip performance.

In many cases, users overlook these aspects. For example, improper spacing between clips can lead to uneven load distribution. Experts highlight that understanding specifications can significantly improve safety and longevity. Regular training on wire rope clip types is beneficial. Employees should know how to select, install, and maintain these tools effectively.

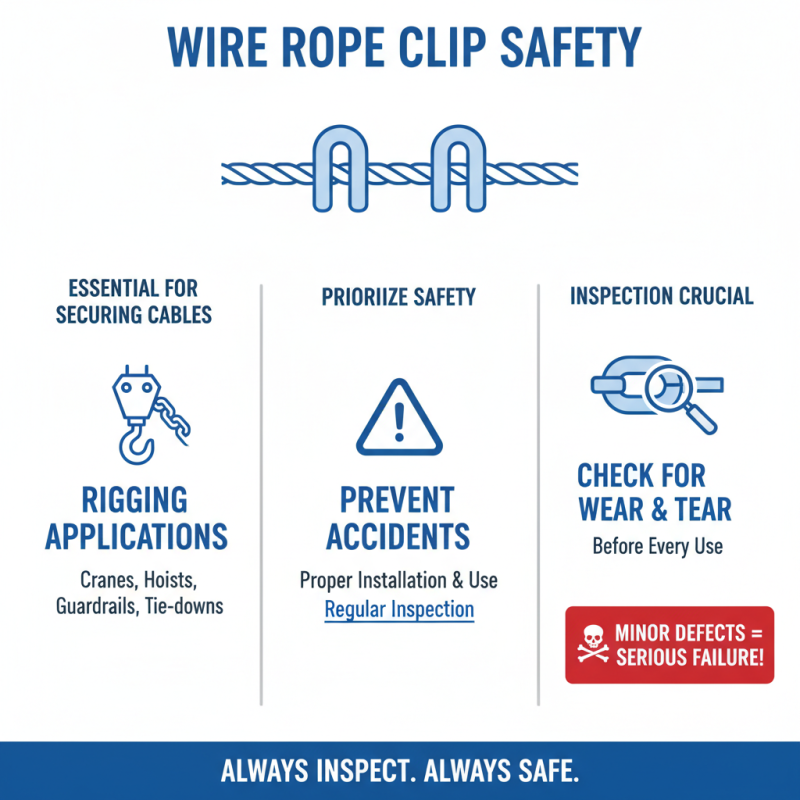

Wire rope clips are essential for securing cables in various rigging applications. However, safety standards must be prioritized to prevent accidents. Proper inspection of wire rope clips is crucial. Check for wear and tear before every use. Even minor defects can lead to serious failures during heavy loads.

When installing wire rope clips, placement is key. Make sure the clips are positioned correctly. Incorrect positioning can lead to slippage. Consider using multiple clips for added security. Aim for a minimum of three clips when securing wire rope ends. This includes understanding the recommended spacing for the clips.

For safe cable clamp usage, remember to check the manufacturer’s specifications. Match the clip size with the wire rope diameter. Ignoring this can result in ineffective gripping. Regular training for personnel involved in rigging is essential. They should be aware of safety standards and practices. Inadequate knowledge may lead to dangerous situations. Therefore, continuous education and hands-on practices are vital.

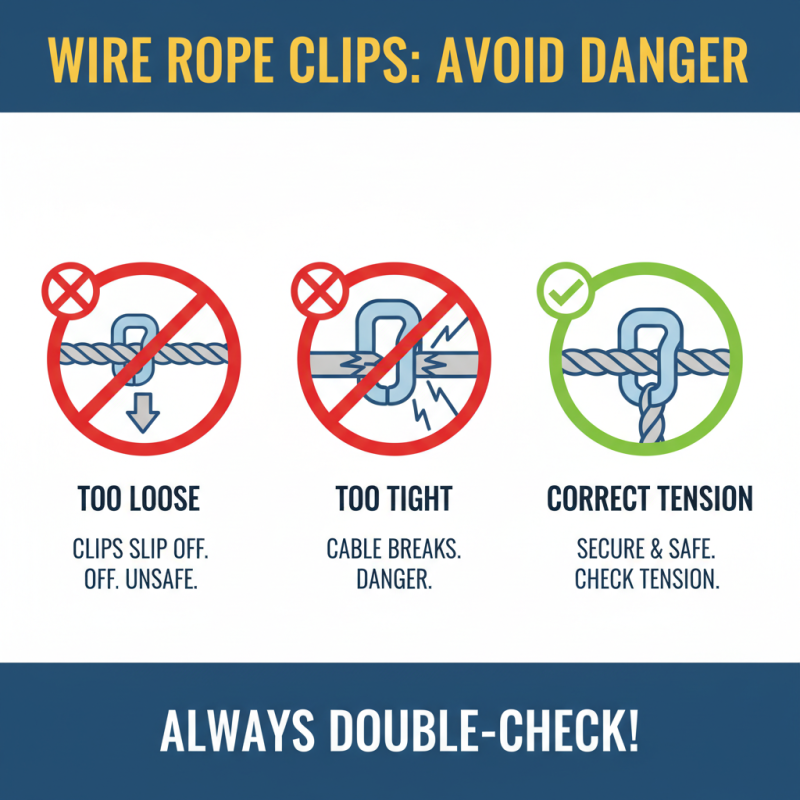

When it comes to wire rope clips, proper installation is key to ensuring safety. A common mistake is over-tightening. This can damage the cable and reduce its effectiveness. Remember, the clip should hold the cable firmly, but not crush it. This balance is crucial for maintaining the strength of the rope.

Another area to consider is the orientation of the clip. Clips should be installed in the correct direction for secure attachment. The U-bolt should always face the dead end of the cable. If this is overlooked, the clip may slip, leading to potential accidents. Pay attention to the number of clips used as well; it's often tempting to underutilize them for efficiency, but this invites risk.

Lastly, inspect your installation regularly. Environmental conditions can affect the performance of wire rope clips. Corrosion and wear can go unnoticed until it's too late. Regular checks help in identifying any potential issues early. Maintaining your equipment is as important as the initial installation. Be vigilant, and don’t take safety for granted.

| Tip | Description | Best Practice |

|---|---|---|

| Selection | Choose the right size and type of wire rope clip based on the cable diameter. | Always refer to manufacturer specifications for sizing. |

| Orientation | Ensure the U-bolt is properly positioned in the saddle. | U-bolt should be on the same side of the cable as the load. |

| Torque | Tighten to the correct torque specifications without over-tightening. | Use a torque wrench for consistent results. |

| Spacing | Leave adequate space between clips for the cable to expand and contract. | Follow recommended spacing guidelines for the cable type. |

| Inspection | Regularly inspect clips for wear, damage, or loosening. | Perform checks at least once a month or before heavy use. |

Using wire rope clips can be tricky. Many people make common mistakes that can lead to unsafe situations. One mistake is improperly tightening the clips. If the clips are too loose, they can slip off. If they're too tight, the cable can break. Always check the tension.

Another mistake is positioning the clips incorrectly. The U-bolt should always be on the dead end of the wire rope. A common error is putting it on the live end, which can cause real trouble. Check the orientation each time you use them.

To ensure safety, remember these tips: use the right number of clips for your application. Using too few clips can put extra pressure on each one. Regularly inspect your clips for wear or damage. Old clips can become unreliable and fail at critical moments. Keep your workspace organized to prevent distractions and mistakes.

Wire rope clips play a crucial role in securing cables. Proper maintenance extends their life and ensures safety. Inspecting clips regularly can prevent accidents. Look for signs of wear and corrosion. Replace any damaged clips immediately.

Keep the clips clean. Dirt and debris can cause corrosion. Use a soft brush to remove buildup. Ensure that clips are correctly installed. An improperly placed clip can lead to failure. Follow the manufacturer's guidelines for installation.

Store wire rope clips in a dry place. Moisture can accelerate rust. Periodically check storage conditions and adjust as needed. Educate your team on the importance of maintenance. A small oversight can lead to significant risks. Remember, safety relies on diligence and care in handling equipment.

This chart illustrates the common maintenance tips for wire rope clips and their corresponding effectiveness in ensuring longevity and safety during use. Regular maintenance is vital for preventing accidents and extending the life of wire rope clips.