When it comes to ensuring the longevity and protection of cables in challenging environments, the importance of choosing the right accessories cannot be overstated. According to industry expert John Simmons, a senior engineer specializing in cable management solutions, “A Heavy Duty Cable Sock is essential for safeguarding against abrasion, impact, and other environmental factors that can compromise cable integrity.” This perspective highlights the critical role that Heavy Duty Cable Socks play in various applications, from industrial settings to outdoor installations.

In an era where durability and reliability are paramount, the demand for robust protective solutions has surged. Professionals across sectors are increasingly recognizing that a well-designed Heavy Duty Cable Sock not only provides protection but also enhances safety by reducing the risk of electrical hazards. With countless options available, selecting the best Heavy Duty Cable Sock can make all the difference in prolonging the life of your cables and maintaining operational efficiency.

In this article, we will explore the top 10 Heavy Duty Cable Socks currently on the market, each offering maximum protection and durability to meet the rigorous demands of modern applications. Whether for professional use or personal projects, understanding the features and benefits of these protective solutions is key to making an informed decision and achieving optimal cable safety.

Heavy-duty cable socks play a crucial role in protecting cables from mechanical damage and environmental hazards. These robust accessories are designed to provide additional strength and insulation, ensuring cables remain safe during both installation and prolonged use. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of cable failures are attributed to external mechanical stresses. Heavy-duty cable socks are specifically engineered to mitigate these risks, thus prolonging the lifespan of electrical installations and contributing to overall system reliability.

The importance of heavy-duty cable socks extends beyond just physical protection. Industry standards indicate that proper cable management can lead to a reduction in downtime and maintenance costs, which can constitute up to 25% of a facility's operational budget. By using heavy-duty cable socks, organizations can significantly enhance safety protocols, as they reduce the likelihood of electrical hazards caused by damaged wiring. Furthermore, their ability to withstand extreme temperatures and harsh environmental conditions makes them indispensable in industrial sectors, where equipment longevity and reliability are paramount.

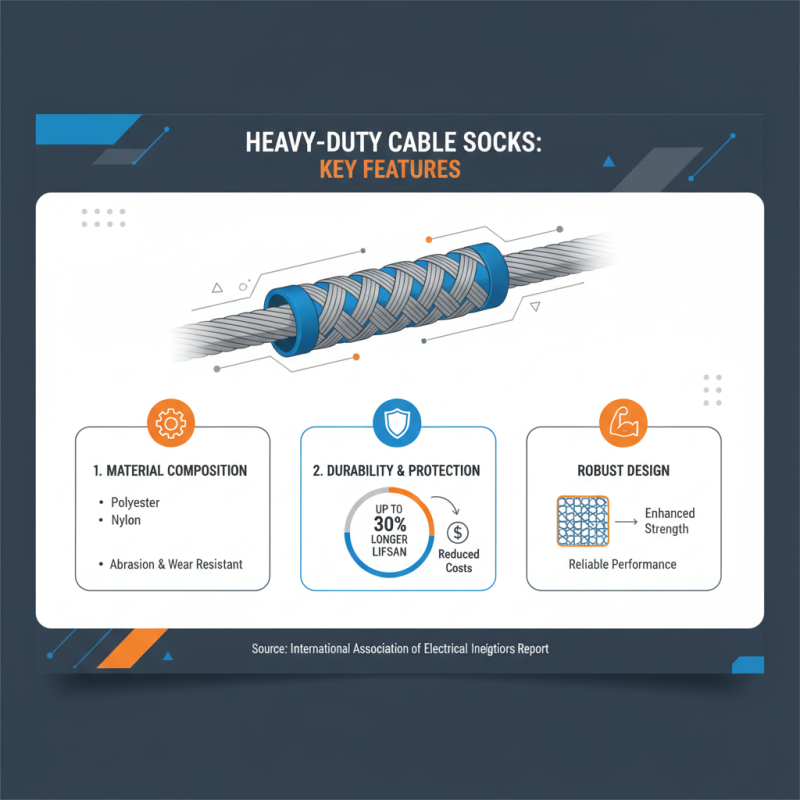

When choosing heavy duty cable socks, several key features play a crucial role in ensuring maximum protection and durability. One of the most important aspects is the material composition. High-quality cable socks are typically made from robust materials such as polyester or nylon, which offer enhanced resistance to abrasion and wear. According to a report by the International Association of Electrical Inspectors, using durable materials can extend the lifespan of protective gear by up to 30%, significantly reducing replacement costs over time.

Another critical feature to consider is the design and fit of the cable socks. A well-designed sock should provide a snug fit without being overly restrictive, allowing for optimal cable management. This is essential as improperly fitted socks can lead to increased strain on cables, potentially resulting in costly downtimes. The National Electrical Manufacturers Association highlights that cables that are adequately protected by properly fitted accessories are 40% less likely to suffer insulation damage, underscoring the importance of this feature in heavy duty applications.

Additionally, resistance to environmental factors such as moisture, chemicals, and UV light is paramount. Heavy duty cable socks that offer these protective qualities are essential for both indoor and outdoor installations, where exposure to harsh conditions is common. The Occupational Safety and Health Administration (OSHA) recommends using protective gear that meets specific resistance standards to ensure worker safety and equipment longevity, with well-tested cable socks reducing incident rates by an estimated 25%. This statistic emphasizes the value of investing in high-quality heavy duty cable socks tailored to withstand challenging environments.

When it comes to protecting your cables from wear and tear, heavy-duty cable socks are an essential investment. These socks, designed to encase cables securely, provide maximum protection against abrasions, cuts, and environmental factors. A recent industry report highlighted that cable damage accounts for approximately 30% of total operational downtime in various settings. This emphasizes the importance of using durable protective equipment, like cable socks, to ensure longevity and reliability.

In this review, we explore the top 10 heavy-duty cable socks currently available, comparing their materials, construction, and protective features. When evaluating these products, look for options made with high-tensile strength fibers that can endure harsh conditions. Many premium cable socks are engineered with properties that resist UV degradation, moisture, and extreme temperatures, contributing to their effectiveness in diverse environments.

Tips: Always measure the diameter of your cables before purchasing cable socks to ensure a proper fit, as a loose sock may not provide the protection needed. Additionally, consider socks with reflective patterns for increased visibility in low-light conditions, enhancing safety in various workplace environments. Choosing cable socks with reinforced ends can also help prevent fraying and extend the product's lifespan, making them a wise choice for extended use.

When it comes to ensuring the longevity and functionality of heavy-duty cables, proper installation and maintenance are crucial. According to industry reports from the Institute of Electrical and Electronics Engineers (IEEE), approximately 30% of cable failures can be attributed to improper installation techniques. To mitigate these risks, it is essential to follow standardized practices for cable sock installation. This includes ensuring that all connectors are secure and that cables are positioned without excessive bending or tension. Utilizing the right tools and protective equipment can also enhance the installation process, reducing the likelihood of damage.

Maintaining cable socks is equally important for sustaining their protective qualities. Regular inspections should be performed to check for signs of wear, such as fraying or displacement of the sock. A report from the National Electrical Contractors Association (NECA) highlights that regular maintenance can extend the life of cable socks by up to 25%. Utilizing cleaning agents that are safe for the materials used in the sock can help to avoid degradation over time. Finally, proper storage of cables when not in use is essential; keeping them in a climate-controlled environment will prevent the buildup of moisture and contaminants, which can lead to premature wear and failure.

This chart displays the tensile strength (in pounds) and temperature resistance (in Fahrenheit) of the top ten heavy-duty cable socks, highlighting their durability and protection features.

Heavy-duty cable socks serve as vital protective solutions across various industries, notably in telecommunications, construction, and electrical applications. Designed to offer maximum durability, they safeguard cables from environmental hazards, mechanical stresses, and incidental damage. In telecommunications, where cables are often exposed to harsh conditions, these socks provide a robust layer of insulation and protection, minimizing the risk of signal degradation.

In construction and outdoor settings, heavy-duty cable socks are indispensable for preventing abrasion and wear. They not only protect the cables but also enhance the overall safety of job sites by reducing the likelihood of tripping hazards. Furthermore, industries dealing with high-voltage equipment benefit substantially from these protective gear, as they can withstand extreme temperatures and resist various chemicals. With their ability to extend the lifespan of cables while ensuring operational efficiency, heavy-duty cable socks are essential across multiple applications.

| Cable Sock Type | Material | Max Load (lbs) | Temperature Range (°F) | Common Applications |

|---|---|---|---|---|

| Standard Heavy Duty | Nylon | 1500 | -40 to 185 | Industrial Machinery |

| Enhanced Thermal | Fiberglass | 2000 | -20 to 1000 | Electrical Insulation |

| Weather Resistant | Polyester | 1200 | -30 to 150 | Outdoor Equipment |

| High Visibility | Reflective Nylon | 1400 | -40 to 170 | Construction Sites |

| Chemical Resistant | PVC | 1000 | -20 to 120 | Chemical Plants |

| Heavy Duty Braided | Polypropylene | 1600 | -10 to 160 | Telecommunications |

| Ultra Heavy Duty | Reinforced Nylon | 2500 | -40 to 200 | Heavy Machinery |

| Anti-Static | Conductive Fiber | 1300 | -20 to 140 | Electronics |

| Waterproof | Neoprene | 1100 | -10 to 130 | Marine Applications |

| Flexible Heavy Duty | Elastomeric | 1400 | -40 to 160 | Automotive Industry |