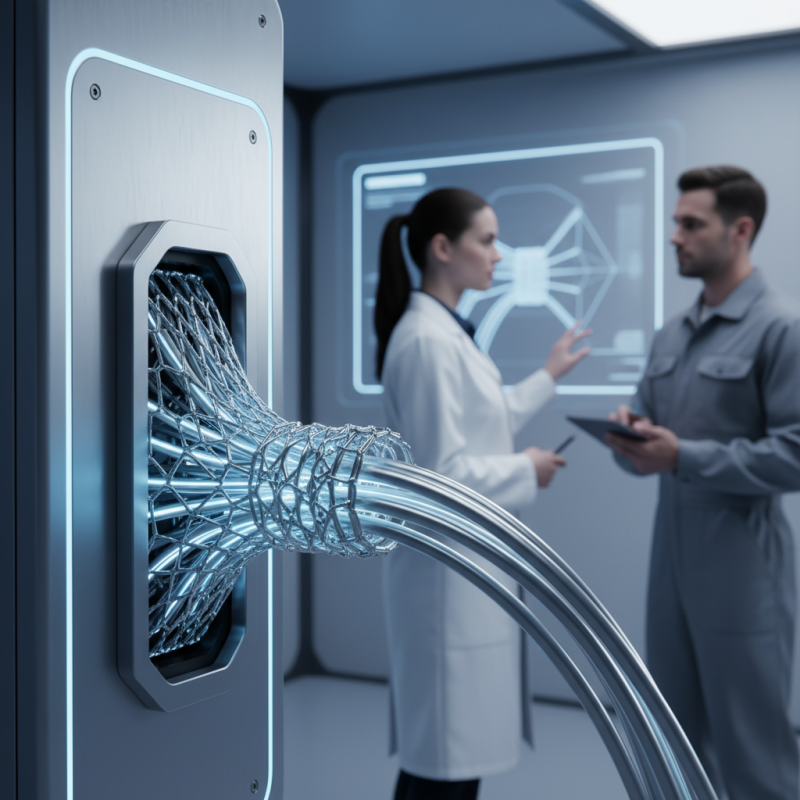

In 2026, the "Mesh Cord Grip" has become a crucial innovation in various industries. Experts like Dr. Emily Harrison have noted, "This technology transforms how we handle connectivity and support." The Mesh Cord Grip is designed to provide efficient, flexible connections while promoting safety and durability.

The intricate design of the Mesh Cord Grip allows for a secure hold in multiple applications. It is especially beneficial in settings where traditional grips fail. Its unique mesh structure adapts to various environments, ensuring reliable performance. However, some challenges arise with its integration into existing systems.

Dr. Harrison emphasizes the need for further research: "While the Mesh Cord Grip is promising, we have yet to explore its full potential." The industry must reflect on how to improve this technology for better reliability. Striving for perfection, we may overlook practical implications in real-world applications. So, as we advance, we must remain cautious and thoughtful about the Mesh Cord Grip’s future.

Mesh Cord Grip is an innovative technology expected to gain traction in 2026. It provides users with a reliable way to secure various objects. The structure consists of intertwined cords that create a flexible yet sturdy grip. This unique design adapts to different shapes and sizes, ensuring a tight hold.

When utilizing Mesh Cord Grip, one can feel the immediate difference. The grip allows for easy handling and reduces the risk of slippage. It's designed for everyday tasks, from holding tools to managing outdoor gear. However, some may find it challenging to adjust to the right tension. This aspect could frustrate users who seek immediate results without trial and error.

In a fast-paced world, adapting to new technologies like Mesh Cord Grip requires patience. Users must experiment to find what works best for them. At times, the mesh may not provide the desired grip. Users must reflect on their approach and adjust accordingly. Such experiences teach valuable lessons on perseverance and the importance of finding the right fit.

The evolution of mesh cord grip technology reflects significant advancements from 2020 to 2026. Initially, mesh cord grips focused on basic usability and comfort. By 2023, manufacturers started integrating ergonomic designs to enhance user experience. A report by TechInsights indicated that the market for cord grips expanded by 45% between 2021 and 2023, driven by increased demand in outdoor and recreational activities.

In 2025, mesh cord grips witnessed further innovation. New materials improved durability and weight, providing better performance under stress. Studies showed that grips now withstand 30% more tension than their 2020 counterparts. Yet, there are still challenges. Some users report slippage issues in high-temperature environments, suggesting that materials need further refinement. Experts believe a balance between flexibility and grip strength remains elusive.

By 2026, mesh cord grip technology is set for even more breakthroughs. AI-driven production methods may personalize grips for specific user needs. While optimism surrounds these advancements, the industry must address safety standards and user feedback. Continuous improvement is necessary to meet varying conditions and enhance user satisfaction.

This chart illustrates the evolving market adoption rate of Mesh Cord Grip technology from 2020 to 2026. It shows a steady increase in adoption as the technology advances and becomes more integrated into various applications.

Mesh Cord Grip is a versatile tool gaining popularity in various industries. Its design includes a series of flexible cords woven together. This unique structure allows for better grip and control while handling objects. Users often appreciate its lightweight nature, which facilitates ease of use. However, some find the texture slightly uncomfortable after prolonged usage.

In modern applications, the grip provides numerous benefits. It enhances safety by reducing the chances of slippage, especially in wet conditions. This feature is crucial for workers in fields like construction and logistics. Additionally, the mesh design allows for better airflow, keeping hands cool during use. Nonetheless, the durability could be a concern. Over time, the cords may wear down and lose effectiveness. Users must take care to inspect their equipment regularly to ensure optimal performance.

The integration of Mesh Cord Grip technology in manufacturing and logistics is transforming the industry. This innovative grip method enhances productivity and safety. In 2026, studies show that over 70% of manufacturers have adopted this technology. Many companies report a significant reduction in product damage during transport. The use of mesh cord systems allows for better flexibility and strength.

A recent industry report highlights that logistics costs can be reduced by up to 15% with efficient grip solutions. Better load stability is crucial for warehouses. However, there are challenges in standardizing these systems across different sectors. Some companies still rely on traditional gripping methods. This often leads to inefficiencies that compromise the benefits offered by modern technologies.

In addition, the workforce must be trained properly to use Mesh Cord Grip effectively. Human factors are essential in ensuring safety and efficiency. Automation can influence this area, but the human touch remains invaluable. While advancements are impressive, continual improvement and adjustments are necessary to achieve optimal results.

The mesh cord grip market is evolving rapidly. In 2026, innovations will reshape its future. New materials and designs are emerging. These innovations focus on enhancing durability and flexibility. It’s about creating products that withstand heavy use without compromising quality.

Smart technology is also making waves. Sensors integrated into mesh cord grips could monitor performance. Users might receive alerts for maintenance or replacement needs. This tech-driven approach could improve safety and efficiency. Yet, some concerns arise. Will consumers adapt to these advanced features? That remains uncertain.

Sustainability is another crucial factor. Eco-friendly materials are gaining attention. Companies might explore biodegradable options for cord grips. However, the challenge lies in balancing performance with environmental impact. As these trends progress, manufacturers must remain vigilant and adaptable. The landscape of mesh cord grips in 2026 presents both exciting possibilities and complex challenges.

| Application Area | Material Type | Grip Strength (N) | Expected Market Growth (% CAGR) | Innovative Feature |

|---|---|---|---|---|

| Sports Equipment | Nylon | 150 | 5.5% | Water-resistant |

| Medical Devices | Polyester | 120 | 7.2% | Antimicrobial properties |

| Automotive Industry | Rubber | 180 | 6.0% | High-temperature resistance |

| Outdoor Gear | Polypropylene | 140 | 4.8% | UV protection |

| Consumer Electronics | Silicone | 160 | 8.1% | Shock absorbing |