The Orchid Turnbuckle Bolt is a vital component in various industrial applications. This bolt allows for the adjustment of tension in cables and rods. According to a report by Grand View Research, the global construction fasteners market is expected to reach USD 132.3 billion by 2025. Such growth highlights the increasing demand for versatile components like the Orchid Turnbuckle Bolt.

In simpler terms, the Orchid Turnbuckle Bolt improves structural integrity. It plays a critical role in tensioning systems. Engineers often rely on it for bridges, buildings, and other infrastructures. Yet, while it provides enhanced stability, the importance of regular maintenance cannot be underestimated. Neglecting this can lead to significant structural failures.

Moreover, accurate installation is crucial. An improperly installed bolt may compromise overall safety. Some users may overlook this aspect, leading to risks. In the fastener industry, awareness and attention to detail are essential for success. As we explore the intricacies of the Orchid Turnbuckle Bolt, let’s remember that precision matters, both in design and execution.

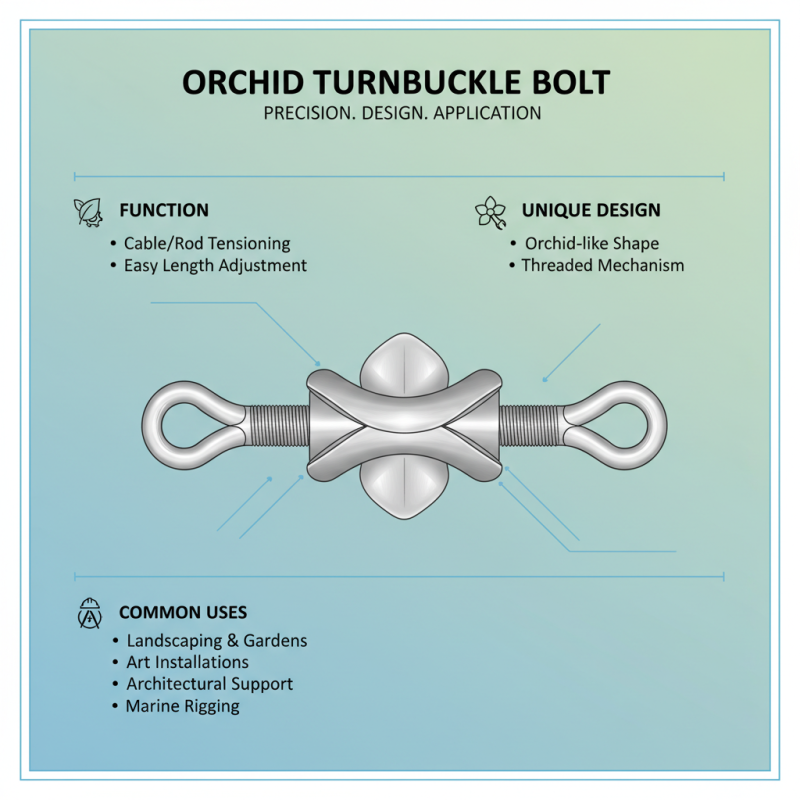

An orchid turnbuckle bolt is a specialized device used to connect and tension cables or rods in various applications. These bolts have a threaded design, allowing for easy adjustments in length. Their unique shape resembles that of an orchid, which differentiates them from traditional turnbuckles. This type of bolt is commonly used in landscaping, art installations, and construction where precise tensioning is required.

The demand for orchid turnbuckle bolts has been increasing. According to industry reports, the market for tensioning devices is projected to grow at a rate of 5% annually. This growth suggests a rising need for efficient solutions in structural stability. Many designers prefer the orchid design for its aesthetic appeal and functionality. However, the use of these bolts can sometimes lead to challenges. Improper installation may cause uneven tension, which can result in structural failure.

Maintenance is crucial for ensuring longevity. Corrosion can weaken the bolts, making regular checks essential. Environmental factors play a significant role in the lifespan of these devices. Some industry professionals argue that despite their benefits, orchid turnbuckle bolts require more robust materials to withstand various conditions. This reflection on their durability prompts further discussion among engineers and designers.

Orchid turnbuckle bolts are essential components in various construction applications. Made from high-strength materials, they are designed to create tension in cables and rods. Common materials include steel and aluminum, which offer durability and resistance to corrosion. These materials are selected based on the specific requirements and environmental conditions of the project.

During installation, the threads of the turnbuckle bolt are twisted to adjust tension. This allows for precise calibration in securing structures. It's common for users to overlook proper tension alignment. Inadequate tension can lead to structural failures. Regular inspections can help identify these issues early.

Tips for using orchid turnbuckle bolts include ensuring proper alignment during installation. Misalignment can cause uneven stress distribution, leading to bolt failure. Always consult guidelines for torque specifications. Using the wrong torque can also result in damage. Proper training and understanding of the installation process are crucial for best results. These considerations can help improve safety and longevity in your projects.

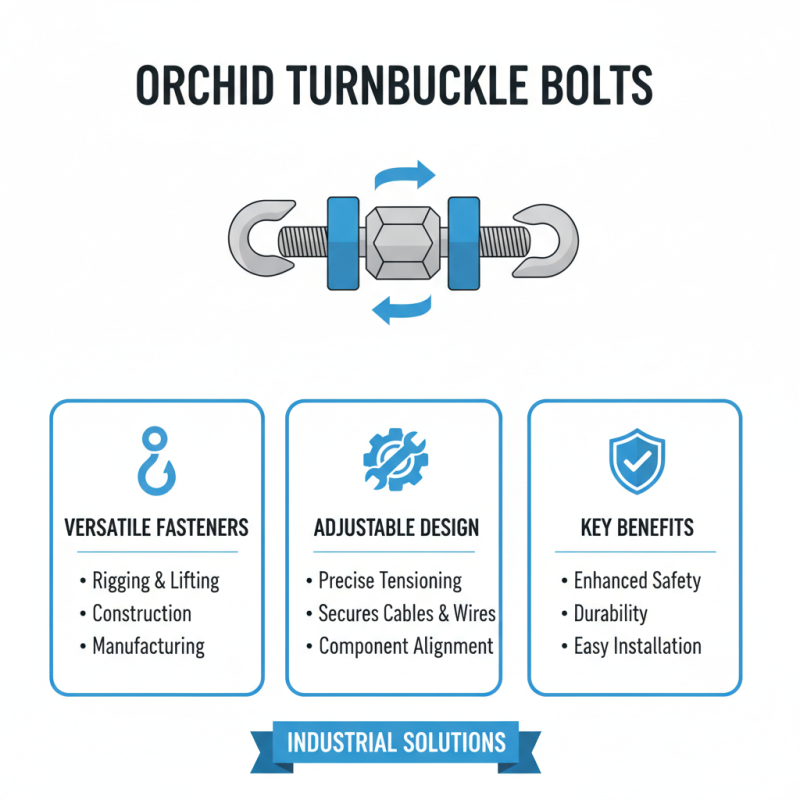

Orchid turnbuckle bolts are versatile fasteners used in various applications. They are commonly found in rigging, construction, and manufacturing. Their adjustable design allows precise tensioning. This feature makes them ideal for securing cables, wires, and other components.

In construction, orchid turnbuckle bolts adjust the tension of guy wires or cables stabilizing structures. For example, they are often used for supporting tall structures or masts. A well-tensioned guy wire ensures safety and stability. Often, workers need to check their tension regularly. It's essential to use them correctly to avoid accidents.

In marine applications, these bolts secure sails or rigging on boats. They can withstand harsh environmental conditions. Yet, saltwater can corrode them over time. Regular inspections are necessary to maintain safety on the water. Remember, not all turnbuckles are created equal. Choosing the right one depends on your specific needs.

Tips for using orchid turnbuckle bolts include checking for wear and tear regularly. Corroded components can lead to failures. Always ensure you have the appropriate size for your application. Over-tightening can damage materials. Be mindful of the load limits as well. Proper installation can make all the difference.

The installation process of orchid turnbuckle bolts is essential for

ensuring structural integrity. Begin with selecting the appropriate size. According to industry standards,

the bolt should match the load requirements. Overestimating or underestimating can lead to failure.

Next, prepare the installation area. Remove any obstacles that might hinder access. A clean workspace improves safety.

Align the bolt with the connection points. Use a level to ensure proper alignment. This step is crucial;

misalignment can cause undue stress on the structure.

Tighten the bolt gradually. The American Society for Testing and Materials (ASTM) recommends specific

torque values based on bolt size. Too tight can lead to material deformation.

Too loose may result in slippage. Inspect your work frequently. Look for signs of wear.

A forgotten step can turn a simple task into a larger issue.

Maintaining orchid turnbuckle bolts is essential for their optimal performance. Regular inspection can prevent significant issues. Check for signs of wear or rust. Look closely at the threads and joints. A simple visual can reveal potential problems. If any bolt appears damaged, consider replacing it immediately.

Cleaning the bolts is also important. Use a soft brush to remove dirt or debris. A damp cloth can help as well. Avoid harsh chemicals that might corrode the metal. Dry the bolt thoroughly after cleaning. Neglecting this step can lead to unexpected failures.

Lubrication is critical too. Apply a light coat of lubricant to the threads. This helps in smooth operation. But don’t overdo it. Excess grease can attract dirt. Keep a routine check. Stay aware of small changes, as they can lead to bigger issues down the line. Regular care ensures longevity and reliability in your turnbuckle bolts.

| Feature | Description | Maintenance Tips |

|---|---|---|

| Material | Typically made from stainless steel or galvanized steel for corrosion resistance. | Regularly inspect for signs of rust or corrosion and apply protective coatings as needed. |

| Function | Used to adjust tension or length in cables or rods, ensuring stability in structures. | Check the tension regularly to ensure safety and structural integrity. |

| Installation | Should be installed in a way that allows for easy adjustments while under load. | Ensure all connections are tight and properly aligned to avoid misalignment. |

| Common Uses | Commonly used in construction, rigging, and marine applications. | Regularly check usage environments for wear and tear due to external factors. |

| Adjustment Method | Turnbuckle design allows for adjustment by turning the central rod. | Use appropriate tools to avoid over-tightening, which can damage components. |