In the realm of rigging and tensioning applications, Wire Rope Turnbuckles play a crucial role in ensuring optimal performance and safety. According to a 2022 report by the National Association of Manufacturers, the demand for precision-engineered rigging solutions, including turnbuckles, has increased by over 15% annually, highlighting their importance in various industries such as construction, maritime, and telecommunications. Properly mastering Wire Rope Turnbuckles not only enhances structural integrity but also extends the lifespan of associated equipment, reducing maintenance costs significantly. By understanding their types, applications, and the best practices for installation and adjustment, professionals can optimize their rigging systems for maximum efficiency and safety. This guide aims to provide an extensive overview of Wire Rope Turnbuckles, empowering users to harness their full potential and make informed decisions in their projects.

Wire rope turnbuckles are crucial components in a variety of industries, providing adjustable tension for cables, ropes, and other types of structure support. Understanding the different types and applications of turnbuckles can significantly impact performance and safety in construction, marine, and industrial settings. According to a report from Research and Markets, the global turnbuckle market is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2027, underscoring the increasing reliance on these devices across sectors.

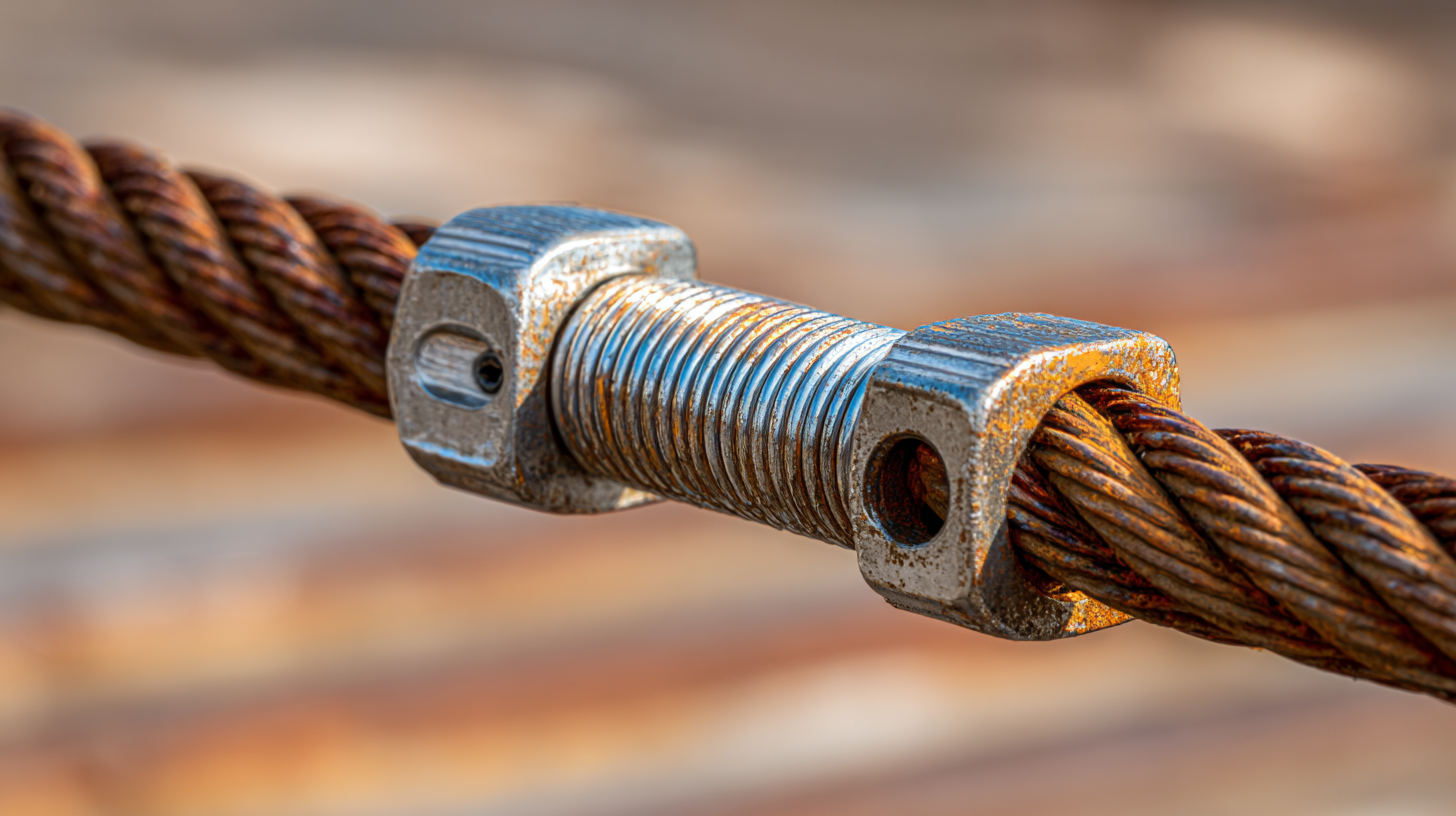

There are three main types of wire rope turnbuckles: body, end fittings, and the adjustment mechanism. The most common types include open-body, closed-body, and jaw-and-eye turnbuckles, each serving distinct functions. Open-body turnbuckles are versatile and widely used, while closed-body turnbuckles offer enhanced strength, making them ideal for heavy-duty applications. A study by the American Society of Civil Engineers also highlights that the correct selection of a turnbuckle can reduce the risk of structural failure by up to 30%, demonstrating the critical role these fittings play in ensuring safety and efficacy in rigging operations.

| Type | Material | Load Capacity (lbs) | Typical Application |

|---|---|---|---|

| Open Body Turnbuckle | Galvanized Steel | 1,200 | Construction |

| Closed Body Turnbuckle | Stainless Steel | 2,000 | Marine Applications |

| Swage Turnbuckle | Aluminum | 800 | Architectural Rigging |

| Fork and Eye Turnbuckle | Carbon Steel | 1,500 | Heavy-Duty Rigging |

| Adjustable Turnbuckle | Brass | 600 | Lightweight Applications |

When embarking on a project that involves mounting 1/8" wire rope cable, the selection of the appropriate turnbuckle is crucial for optimal performance. While some may believe that turnbuckles are essential for tensioning stainless steel wire ropes, there are effective alternatives, especially for applications like wooden balusters. By utilizing the right hardware, you can maintain the integrity and aesthetic of your project without the added complexity of turnbuckles.

Choosing the right wire rope turnbuckle depends largely on the specific requirements of your installation. Factors such as load capacity, tensioning mechanism, and environmental conditions should guide your selection. Moreover, for projects that prioritize simplicity and clean lines, options that do not require turnbuckles might be advantageous, Streamlining the assembly process can lead to a more efficient build that not only looks great but performs exceptionally well. Exploring innovative deck hardware celebrated in recent championships could also provide insights into advanced solutions for your wire rope cable installations.

Wire rope turnbuckles are critical components in many structures, ensuring optimal tension while maintaining flexibility. When installing these devices, understanding essential techniques is paramount for achieving peak performance. According to a recent industry report, improper installation can reduce the lifespan of wire rope systems by up to 30%, highlighting the need for expertise in this area.

One key installation technique involves the precise alignment of the turnbuckle with the wire rope. When installing, it's crucial to ensure that the turnbuckle is not overtightened, as too much tension can lead to metal fatigue and catastrophic failure. A study by the International Organization for Standardization indicates that achieving the correct tension can improve safety margins and enhance the functionality of the entire system.

Furthermore, regular inspection and maintenance of turnbuckles can mitigate risks associated with wear and tear. Regular checks can identify issues like corrosion or misalignment, which can lead to serious safety concerns if left unaddressed. Industry experts recommend establishing a routine maintenance schedule that includes detailed inspections and timely replacements, keeping the operational integrity of wire rope systems intact.

Wire rope turnbuckles are essential components in various applications, from construction to maritime uses. To ensure their optimal performance, regular maintenance is crucial. According to industry experts, corrosion is one of the primary causes of turnbuckle failure. It is recommended to inspect these devices at least once every three months, particularly in environments exposed to moisture or chemicals. A study by the American Society of Mechanical Engineers reveals that proper maintenance can extend the lifespan of wire rope components by up to 50%, ultimately enhancing safety and efficiency.

Lubrication is another key factor in maintaining turnbuckles. Using the right type of lubricant can significantly reduce friction and wear, ensuring smooth operation. A report by the International Organization for Standardization indicates that regularly lubricating wire rope systems can reduce maintenance costs by 20% over five years. Additionally, it helps in preventing galling, which can lead to catastrophic failures. Adhering to these maintenance tips will not only prolong the life of the turnbuckles but also minimize the risk of operational hazards, making it imperative for professionals to prioritize these practices.

This chart displays the maintenance frequency and performance rating of wire rope turnbuckles based on various maintenance practices.

When it comes to wire rope turnbuckles, ensuring optimal performance relies heavily on avoiding common mistakes that can compromise their effectiveness. One prevalent error is the inadequate tightening of turnbuckles. Research indicates that under-tightened turnbuckles can weaken the overall tension in the system, leading to potential failures under load. According to industry reports, maintaining the right tension is crucial, as a properly calibrated turnbuckle can increase the load-bearing capacity of wire rope systems by up to 50%.

Another critical mistake is neglecting regular inspections. Many users assume that turnbuckles are maintenance-free, but a lack of regular checks can lead to unnoticed wear and tear. Data shows that nearly 30% of equipment failures in rigging systems are due to overlooked maintenance issues. Ensuring that turnbuckles are thoroughly examined for signs of corrosion or stress fractures can significantly extend their lifespan and maintain safety standards.

Lastly, using the wrong type of turnbuckle for a specific application can lead to suboptimal performance. Turnbuckles come in various styles and materials, each suited for different environments and loads. Selecting the right turnbuckle can enhance efficiency and durability; industry studies have shown that appropriate material choices can increase the longevity of rigging setups by more than 40%. Being mindful of these mistakes not only optimizes performance but also ensures safety in all applications involving wire rope turnbuckles.