In the realm of efficient cable installation, the importance of utilizing the right tools cannot be overstated. One such invaluable tool that has emerged as a game changer in the industry is the Underground Cable Pulling Sock. Designed specifically to enhance the cable pulling process, these innovative socks streamline operations, ensuring that cables can be installed quickly and effectively in challenging underground environments.

The Underground Cable Pulling Sock provides significant advantages over traditional methods, reducing friction and preventing damage to the cable insulation during installation. Its unique design allows for smoother cable movement through conduits, minimizing the risk of snags and kinks that can complicate the installation process. As professionals increasingly recognize the benefits of adopting advanced tools, the Underground Cable Pulling Sock stands out as a vital asset for achieving optimal results in various cable installation projects.

In conclusion, embracing the use of Underground Cable Pulling Socks not only enhances the efficiency of the installation process but also contributes to the longevity and reliability of the cables being installed. With this tool, cable installation teams can ensure a faster, safer, and more efficient workflow, ultimately leading to improved project outcomes and customer satisfaction.

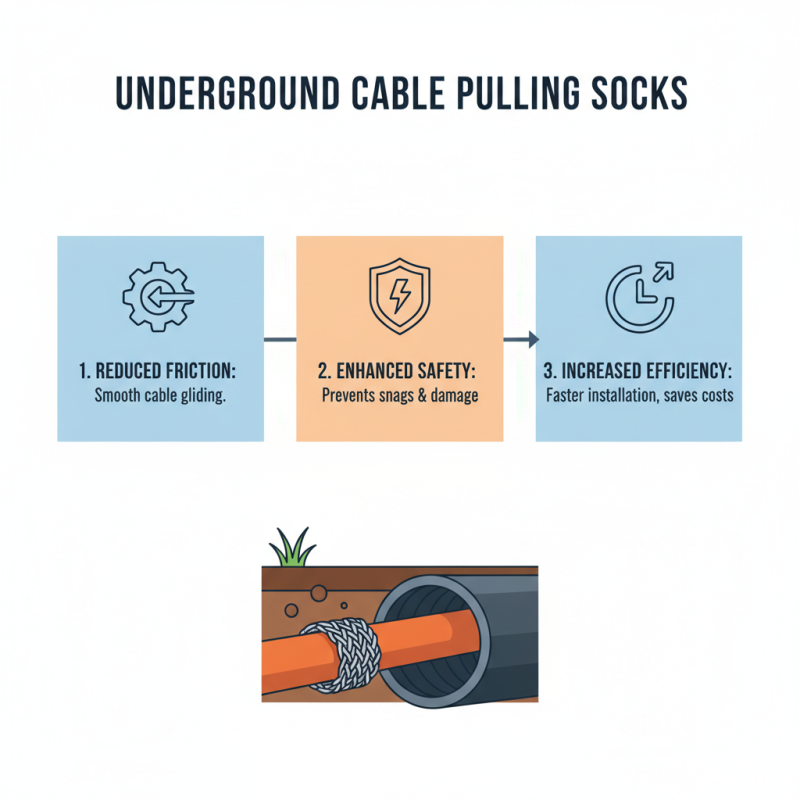

Underground cable pulling socks are innovative tools designed to enhance the efficiency and safety of cable installation processes. One of the primary benefits of using these socks is their ability to reduce friction during cable pulls. Made from durable materials, they help the cable glide smoothly through conduits and other tight spaces, significantly lowering the risk of snagging or damage. This friction reduction not only preserves the integrity of the cables but also enables quicker installations, saving both time and labor costs.

Another advantage of underground cable pulling socks is their role in protecting both the cable and working crew during installations. The socks encapsulate and shield the cable, preventing abrasion from contact with rough surfaces within conduits. This protective feature is vital for maintaining cable quality over time and minimizing maintenance needs. Additionally, using pulling socks can enhance worker safety by reducing the chances of sudden jerks or pulls, which can lead to accidents. Their ergonomic design allows for a more comfortable grip, making the installation process smoother and more manageable, especially in challenging underground environments.

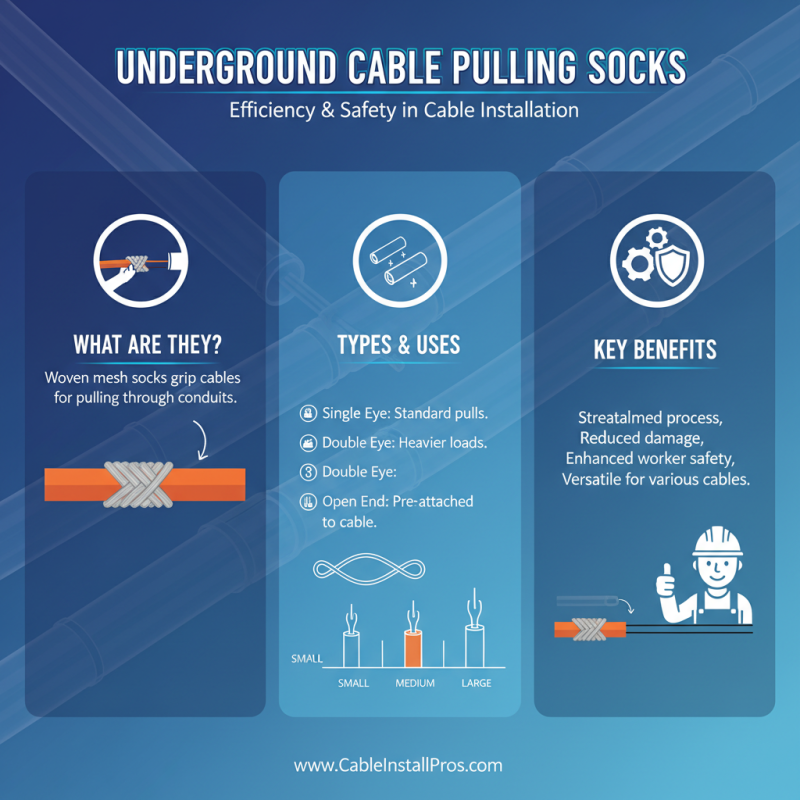

When it comes to underground cable installation, utilizing the right tools can significantly enhance the efficiency and safety of the process. Among essential equipment, underground cable pulling socks stand out due to their ability to streamline the pulling of cables through conduits and ducts. These specialized socks come in various types, each designed to cater to different cable sizes and installation requirements.

One common type of underground cable pulling sock is the woven fabric sock, designed for use with larger cables. Made from durable materials, these socks provide a sturdy grip around the cable, minimizing the risk of damage during the installation process. Additionally, there are lightweight nylon socks suited for smaller cables that protect and ease the pulling process. These socks often feature reinforced ends that help prevent fraying, ensuring the longevity of the tool and the integrity of the cable.

Another notable classification includes tubular pulling socks, which are easily adjustable to accommodate varying cable diameters. These socks not only provide a secure fit but also allow for quick adjustments in the field, making them an excellent choice for dynamic installation environments. By choosing the appropriate type of cable pulling sock, installers can enhance efficiency and reduce the risk of costly mishaps during the cable pulling process.

Cable pulling socks are essential tools in the installation of underground cables, providing a host of benefits that improve both efficiency and safety. Proper use of cable pulling socks can significantly enhance the installation process. According to industry reports, efficient cable pulling methods can reduce installation time by up to 30%, minimizing labor costs and project timelines. When using these socks, it is crucial to ensure that the sock is adequately sized for the cable being pulled, as improper sizing can lead to damage or cable failure.

To effectively employ cable pulling socks, it is important to follow specific guidelines. First, always inspect the socks for wear or damage before each use. A well-maintained sock allows for a smoother pull and reduces friction, which can otherwise increase the risk of cable insulation damage. When attaching the sock to the cable, the connection should be secure, typically using a tapered end to allow for gradual tension and to prevent jamming. The National Electrical Contractors Association emphasizes that pulling should be done steadily and without sudden jerks to minimize stress on both the cable and the pulling sock, which can lead to improved longevity and reliability of the installed cable system. Proper training and adherence to these practices can further elevate the effectiveness of cable pulling operations in various applications.

| Dimension | Description | Importance | Proper Use Guidelines |

|---|---|---|---|

| Material | Typically made from nylon or polyester for durability and flexibility. | Ensures the sock can handle heavy cables and rough surfaces. | Choose a sock made of high-quality material for better performance. |

| Size | Available in various sizes to accommodate different cable diameters. | Correct size prevents cable damage during installation. | Measure cable diameter before selecting a sock size. |

| Grip | Features friction-reducing surfaces to facilitate pulling. | Improves cable handling and reduces risk of entanglement. | Ensure proper alignment of the sock to avoid snags during pull. |

| Usage Environment | Designed for underground installation in various soil conditions. | Extends cable lifespan when used in appropriate conditions. | Confirm soil type and environmental factors before installation. |

| Installation Technique | Involves careful handling and securing of cables within the sock. | Minimizes damage and ensures smoother installation process. | Follow manufacturer instructions for optimal installation steps. |

In the realm of cable installation, professionals frequently encounter various challenges that can hinder efficiency and increase project timelines. One significant issue is the friction between the cable and the conduit, which can make pulling cables through tight or complex pathways difficult. Additionally, harsh environmental conditions, such as moisture and dirt, can introduce additional resistance when maneuvering cables. These obstacles not only complicate the installation process but also raise the risk of damaging sensitive cable components.

This is where the use of underground cable pulling socks comes into play. These specially designed accessories help to minimize friction, as they allow the cable to glide smoothly through conduits, thus facilitating a more seamless installation. The socks provide an extra layer of protection against environmental factors, shielding the cable from moisture and debris that could otherwise compromise its integrity. By improving the efficiency of cable pulling, socks help to mitigate downtime and reduce labor costs, ultimately leading to more successful project completions.

When utilizing underground cable pulling socks, it's crucial to implement best practices to enhance their longevity and maintain efficiency throughout the installation process. Regular inspections before each use can prevent potential issues. According to industry reports, worn or damaged socks can lead to increased friction and potential cable damage, resulting in costly delays during installation. It's vital to check for signs of wear and ensure the socks are free from sharp debris that could compromise their integrity.

One effective tip is to clean the cable pulling socks regularly. A simple wash with water and gentle soap can remove dirt and debris that may accumulate during the pulling process. This step not only extends the sock's lifespan but also ensures a smoother pulling experience. Additionally, applying a light lubricant can minimize friction, making it easier to pull cables over long distances.

Another best practice is to store cable pulling socks in a dry, cool place when not in use. Keeping them free from heavy weight and avoiding direct sunlight can prevent premature deterioration. Reports suggest that proper storage can significantly increase the lifespan of these tools, allowing for more efficient cable installation when they are needed. Implementing these practices ensures that cable pulling socks remain in optimal condition, resulting in safer and more effective installations.