In the realm of lifting and pulling heavy loads, the effectiveness of tools can greatly influence both safety and efficiency on the job. One such invaluable tool is the Wire Rope Grip Puller, a device renowned for its robustness and versatility. As industry expert John Anderson, a veteran in rigging and lifting techniques, aptly states, “A Wire Rope Grip Puller is not just a tool; it’s a lifeline in ensuring tasks are completed effectively and without compromise.”

Harnessing the capabilities of a Wire Rope Grip Puller allows professionals to tackle challenging lifting and pulling operations with confidence. Whether in construction, maintenance, or any field that involves heavy lifting, understanding how to properly utilize a wire rope grip puller can lead to significant improvements in workflow and safety protocols. As we delve into the mechanics and best practices associated with this essential tool, we will explore key techniques and strategies for maximizing its potential, ensuring that users can handle both routine and complex lifting tasks with ease.

Wire rope grip pullers are essential tools in various industries, providing a reliable solution for efficient pulling and lifting tasks. Understanding the basics of these devices is crucial for optimizing their usage and ensuring safety. A wire rope grip puller operates by clamping onto a wire rope and utilizing mechanical advantage derived from pulleys and levers. According to the Lifting Equipment Engineers Association (LEEA), proper understanding of the equipment can lead to a significant increase in operational efficiency, potentially reducing work time by 30% in some applications.

When selecting a wire rope grip puller, it is important to consider the load capacity and the type of wire rope being used. The Occupational Safety and Health Administration (OSHA) stipulates that the working load limit (WLL) should be clearly marked and must be adhered to in order to prevent accidents. Additionally, regular maintenance and inspection of the puller can enhance durability and performance, as reported by the International Organization for Standardization (ISO). By understanding the mechanism and specifications, operators can ensure that they are equipped to handle jobs ranging from construction to heavy machinery repair effectively and safely.

When choosing the right wire rope grip puller for your needs, it’s essential to consider several factors that will impact both functionality and safety. Firstly, determine the weight capacity required for your pulling or lifting task. Wire rope grip pullers come in various capacities, typically ranging from a few hundred to several thousand pounds. Assessing the load you need to manage will help you select a puller that can perform effectively without risking equipment failure or injury.

Next, evaluate the design features of the wire rope grip puller. Look for options that include adjustable grips, which can accommodate various wire rope sizes for versatility in different scenarios. The length of the wire rope is also crucial; longer ropes provide increased reach and flexibility but may add weight. Additionally, check if the puller has safety features, such as overload protection or robust locking mechanisms, which enhance operational safety. By examining these key elements, you can select the optimal wire rope grip puller that meets your specific requirements and ensures efficient, reliable performance in your pulling and lifting applications.

To effectively set up a wire rope grip puller, begin by selecting the appropriate model based on your specific lifting and pulling requirements. According to a report by the Lifting Equipment Engineers Association (LEEA), proper selection is crucial, as different pullers have varying capacities, typically ranging from 1 ton to over 10 tons. Ensure that the wire rope grip puller you choose can handle at least 10% more than your maximum expected load to maintain a safety margin.

Once you have your puller, begin by inspecting all components for any signs of wear or damage. This includes checking the wire rope for fraying and ensuring that the grip mechanism functions correctly. Set up the puller by anchoring it securely to a stable point, which is vital for safety and performance. The LEEA emphasizes that improper anchoring can lead to equipment failure. After anchoring, attach the wire rope and check that it is wound correctly around the drum mechanism.

Perform a test pull to confirm all components function seamlessly before assuming full load operations. This methodical approach not only maximizes efficiency but also enhances safety during use.

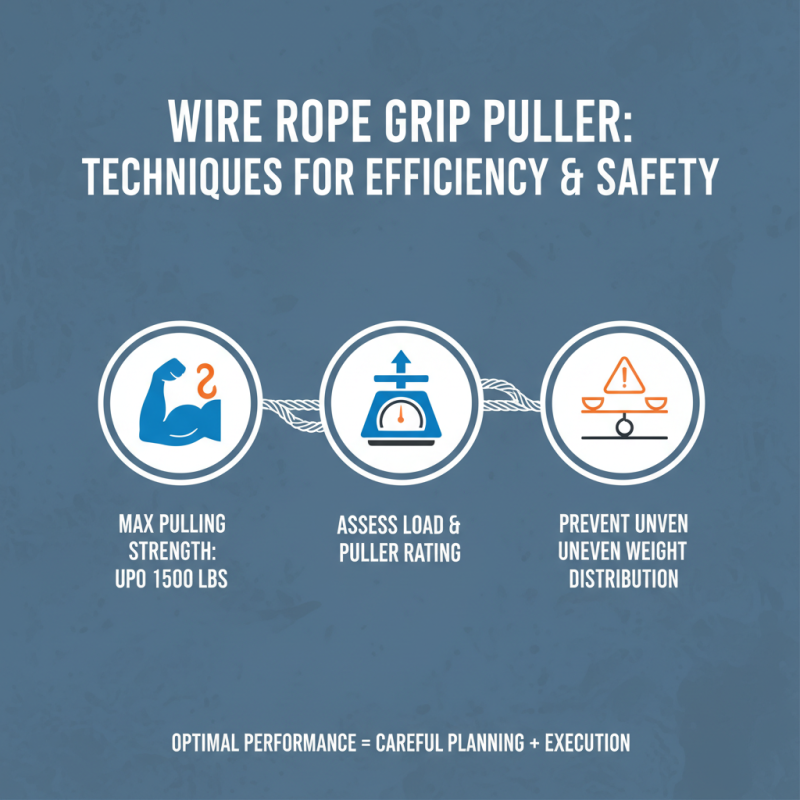

When using a wire rope grip puller, mastering effective pulling and lifting techniques is vital for maximizing efficiency and safety. A well-designed grip puller can handle heavy loads, often boasting a maximum pulling strength of up to 1,500 pounds, depending on the model and specifications. To achieve optimal performance, it's important to assess the load's weight and ensure that the puller is rated accordingly. Always keep in mind that uneven weight distribution can lead to equipment failure or accidents, highlighting the importance of careful planning and execution.

Tips for efficient pulling include ensuring the wire rope is free of kinks and obstructions, as these can cause friction and reduce efficiency. Moreover, positioning the grip puller at a proper angle can significantly enhance leverage, reducing the effort required. Industry reports indicate that proper use of grip pullers can reduce manual lifting injuries by over 30%, underlining the importance of ergonomic practices in lifting and pulling tasks.

Moreover, using a secure anchoring point can further stabilize the load during operation. Avoid pulling from the side, as this can compromise the integrity of the wire rope and result in accidents. Always check for wear and tear on the equipment before utilizing it, as well-maintained tools are essential for safe operations. Utilizing these techniques not only ensures effective performance but also promotes a safer working environment, making the most out of a wire rope grip puller.

When using a wire rope grip puller, safety should always be the foremost concern. Ensure that you wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to protect yourself from potential hazards. Before initiating the pulling or lifting process, inspect the equipment thoroughly for any signs of wear or damage. Check the wire rope for fraying or kinks and confirm that the grip puller is properly attached and functioning. An unsafe setup can lead to accidents, so taking the time for these important checks is essential.

Another vital aspect of safety is maintaining proper body positioning. Stand clear of the pulling line and keep bystanders at a safe distance to avoid injuries caused by sudden slips or breaks in the cable. It's also recommended to use the puller on a stable surface; if the equipment needs to be used on uneven ground, make sure to stabilize it adequately. Additionally, never exceed the manufacturer's specified weight limits, as doing so could compromise the integrity of the equipment and pose serious risks. Following these best practices will help ensure a safer working environment when using a wire rope grip puller.