In the realm of rigging and heavy lifting, a Wire Rope Turnbuckle serves as a pivotal component that ensures safety and efficiency. Renowned rigging expert, John Smith, emphasizes the importance of this device by stating, “A properly adjusted Wire Rope Turnbuckle is essential for achieving tension and stability in any rigging operation.” This simple yet effective tool allows for the adjustment of tension in cables, making it indispensable in various applications, from construction sites to maritime operations.

The Wire Rope Turnbuckle works by utilizing a threaded adjustment mechanism, which can either tighten or loosen the cable, providing a versatile solution to meet the dynamic demands of rigging. Understanding how to effectively use and maintain a Wire Rope Turnbuckle is crucial for professionals in the industry, as it directly impacts the safety and integrity of the load being managed. Moreover, it is critical for users to recognize the specific types and their appropriate uses, as different scenarios call for different configurations of this essential rigging accessory. As rigging continues to evolve, the Wire Rope Turnbuckle remains a testament to the ingenuity and practicality required in modern lifting and securing operations.

A wire rope turnbuckle is a crucial component in rigging systems, serving to adjust the tension and length of wire ropes and cables efficiently. Essentially, it consists of a metal frame with threaded ends that hold either a hook, eye, or another connector. The design allows for quick adjustments to be made on-site, enhancing the overall safety and performance of rigging applications, especially in construction and marine environments. According to a recent industry report, over 60% of rigging professionals cite turnbuckles as essential tools for maintaining structural integrity in various applications.

In rigging systems, turnbuckles play a significant role in tensioning the wire rope or cable, ensuring that the load remains stable and secure. This adjustment is crucial in preventing overloads that could lead to catastrophic failures. The projected growth of the rigging equipment market, expected to reach approximately $2.5 billion by 2025, highlights the ongoing demand for reliable tensioning solutions like turnbuckles within several industries including agriculture, construction, and entertainment.

Tip: When using turnbuckles, ensure to regularly inspect them for any signs of wear or fatigue, as this can significantly affect the safety and performance of your rigging systems. Another important consideration is to choose the appropriate turnbuckle size and type based on the specific load requirements and environmental conditions to maximize effectiveness.

A wire rope turnbuckle is a vital element in rigging systems, providing a means to adjust the tension and length of wire ropes. Understanding its key components is essential for effective usage. The primary parts of a turnbuckle include the body, end fittings, and the adjusting mechanism. The body, typically made of robust materials like steel, provides the structural integrity necessary to withstand significant loads. The end fittings, which come in various forms such as hooks, eyes, or loops, connect the turnbuckle to the wire rope, allowing for versatile configurations depending on the rigging requirements.

The adjusting mechanism is where the magic happens. It generally consists of threaded rods that enable the length of the turnbuckle to be altered. By rotating the body of the turnbuckle, the tension in the wire rope can be easily increased or decreased. This adjustability is crucial for ensuring proper tensioning in rigging applications, preventing slack that could lead to failures or accidents. Understanding these components allows riggers to effectively utilize wire rope turnbuckles in a safe and efficient manner, enhancing overall performance in various lifting and securing tasks.

| Component | Description | Function | Material |

|---|---|---|---|

| Body | The main body of the turnbuckle, typically cylindrical in shape. | Houses the adjusting mechanism and connects to both ends of the rigging. | Steel or Aluminum |

| Ended Fittings | Attachments at each end of the turnbuckle (e.g., hooks, eyes). | Connects the turnbuckle to the wire ropes or other rigging components. | Steel |

| Adjustment Mechanism | The internal thread or system that allows the turnbuckle to be tightened or loosened. | Provides tension control for the rigging assembly. | Steel |

| Nut | A component that secures the ends of the turnbuckle and allows for adjustment. | Ensures that the turnbuckle maintains its position after adjustment. | Steel or Nylon |

| Locking Mechanism | Safety feature to prevent accidental loosening during operation. | Ensures safety and reliability in high-stress settings. | Metal or Composite |

Wire rope turnbuckles play a crucial role in rigging systems, especially when it comes to load adjustment and tension optimization. One of the primary benefits of using wire rope turnbuckles is their ability to provide precise tension control. This is essential in various applications, from construction to boating, where maintaining the correct tension ensures the safety and integrity of the rigging system. By simply rotating the turnbuckle, users can easily tighten or loosen the wire rope, allowing for quick adjustments without the need for intricate tools.

In addition to enhancing safety, wire rope turnbuckles contribute to increased stability in rigging setups. Properly tensioned cables can help prevent issues such as slack, swaying, or excessive load on particular components. This stability is particularly beneficial in environments subject to dynamic forces, such as wind or vibration, where secure tensioning can significantly reduce wear and tear. The ease of adjustment offered by wire rope turnbuckles makes them an ideal solution for applications requiring frequent changes in load or positioning, further underscoring their value in efficient rigging practices.

Proper installation and tensioning of wire rope turnbuckles is crucial for ensuring safety and effectiveness in rigging applications. To begin the installation process, first, ensure that the turnbuckle is compatible with the wire rope being used. It is essential to inspect both the turnbuckle and wire rope for any signs of wear or damage before proceeding. Once confirmed, secure one end of the wire rope to a fixed anchor point, looping it through the turnbuckle's hook or eye. When looping the wire rope, it is important to maintain a proper bend radius to avoid weakening the rope.

After securing the wire rope, the next step is to tension the turnbuckle. By turning the body of the turnbuckle in a clockwise direction, you can draw the wire rope tighter. It’s important to apply tension gradually; excessive force could lead to damage or failure of the components. A good practice is to periodically check the tension and re-adjust as needed to ensure that the rigging stays secure throughout its use. Remember to follow safety protocols during installation and inspection, as proper procedures significantly reduce the risk of accidents in rigging scenarios.

This bar chart illustrates the tension levels for different load categories using wire rope turnbuckles, ranging from light to maximum loads. Proper installation and tensioning of turnbuckles are essential for safe rigging practices.

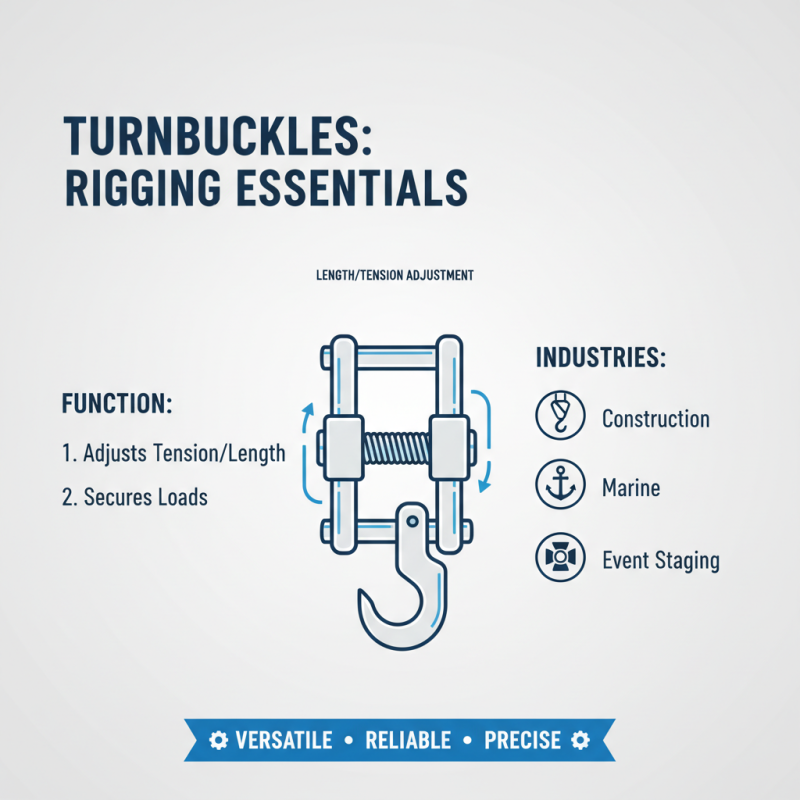

Turnbuckles are essential components in rigging, commonly used to adjust the tension or length of wire ropes and cables. They consist of a metal frame with two threaded ends, allowing for precise adjustments. In various industries, including construction, marine, and event staging, turnbuckles serve crucial roles in securing loads, maintaining tension in suspension systems, and balancing the stresses in rigging assemblies. Their versatility and effectiveness make them a popular choice among riggers and engineers alike.

When selecting turnbuckles for specific applications, it's important to consider the industry standards that govern their use. Standards such as ASTM F1145 for turnbuckles in general rigging and other relevant safety codes ensure that these devices meet crucial strength and performance requirements. Utilizing turnbuckles that conform to these standards not only enhances safety but also promotes efficiency in rigging setups.

Tips for safe turnbuckle usage include regularly inspecting for wear and tear, ensuring the correct load capacity is selected for the task, and utilizing the appropriate tools for adjustments. Additionally, always follow manufacturer guidelines and safety protocols to minimize risks during rigging operations. Proper training and knowledge of turnbuckle use can significantly enhance the safety and effectiveness of rigging practices across various applications.