General Information On Wire Ropes

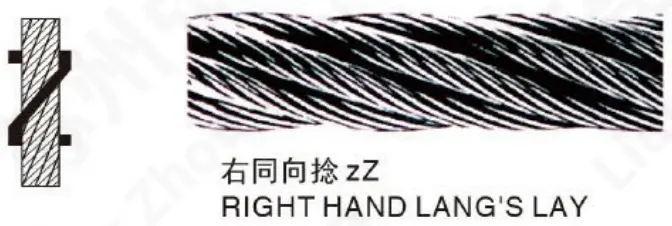

Type Ans Direction Of Lay

Right Hand Ordinary Lay

Left Hand Ordinary Lay

Right Hand Lang’s Lay

Left Hand Lang’s Lay

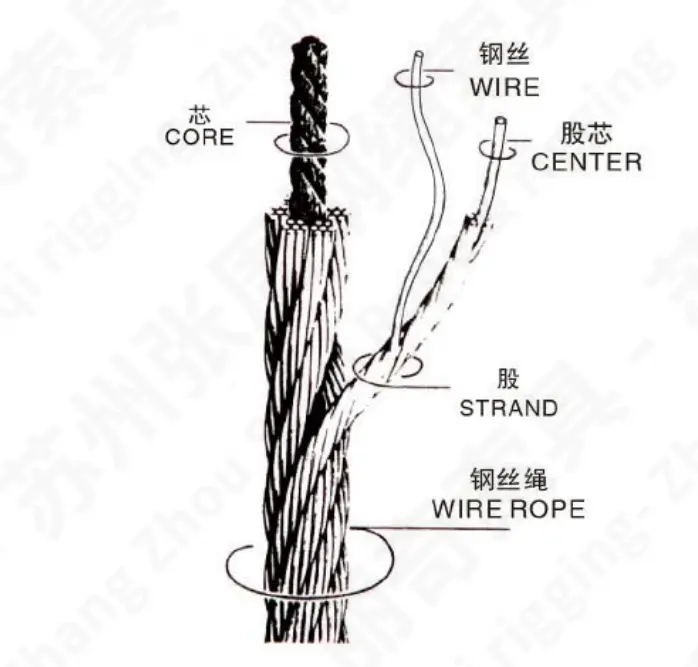

Basic Structure Of Wire Rope Is As Follows:

Core, Wire, Center, Strand, Wire Rope

Issues related to the specific operation of wire rope during use

1.when choosing wire rope should consider the safety factor, this is very important for safety production, safety factor more small,more dangerous, even if no broken,lifetime of the rope will shorten, the load object safety factor of Steel Wire rope not less than 4 times, the human is not less than 10 times.

2.Put a rope method is the key before using,the right method can eliminate the stress inside the rope,if method is not correct,it will increase the internal force,it is very harmful for using.

3.It is forbidden to use when wire rope is overload,should not be affected by the impact,don't make the wire rope touch the sharp corner when strapping or lifting goods,please put the wood, canvas or sacks when touching.Or with special corner protector to prevent the main object of wire rope, produce equipment and personal injuries.

4.Multiple strands wire rope should be fixed and then cut, prevent outer layer loose due to cutting,affect the service life.

Hot dip galvanized steel wire rope

Hot dip galvanized steel wire rope is a critical component in industries.It is the Market trend and will become the first choice of galvanized steel wire rope users. Because hot-dip galvanized steel wire rope has an extremely high cost-effectiveness. hot-dip galvanized steel wire rope is coated by physical thermal Diffusion. First, iron Zinc compounds is formed, and then pure zinc layer is successively formed on the surface of iron Zinc compounds on the surface of galvanized steel wire.

The common types of wire rope constructions

There are 6x19 Wire Rope,6x36 Wire Rope,7x19 Wire Rope

6x19 Wire Rope: This particular construction is strong and abrasion-resistant, yet not highly flexible. This construction provides a balance between flexibility and strength. It's often used in applications where the rope needs to bend and flex but still carry significant loads. It's popular for general-purpose lifting and hoisting.

6x36 Wire Rope: The 6x36 construction offers improved flexibility compared to 6x19. This flexibility makes it suitable for applications that require the rope to navigate pulleys and sheaves while carrying heavy loads. It's commonly used in crane systems, winches, and elevator cables.

7x19 Wire Rope:7x19 wire rope is incredibly flexible that makes it ideal for applications where bending and maneuvering are necessary. It's frequently used in control cables, aircraft control surfaces, and other applications where precise control and flexibility are required.

In all these constructions, the number of wires in each strand, the layout of the strands, and the materials used can vary depending on the specific requirements of the application. The choice of wire rope construction should be based on factors such as load capacity, flexibility, durability, and resistance to environmental factors like corrosion. It's important to consult with a wire rope expert to select the right construction for your specific needs. To that end, connect with Zhangzhou steel wire rope and let us help you to choose !