Coated Wire Rope

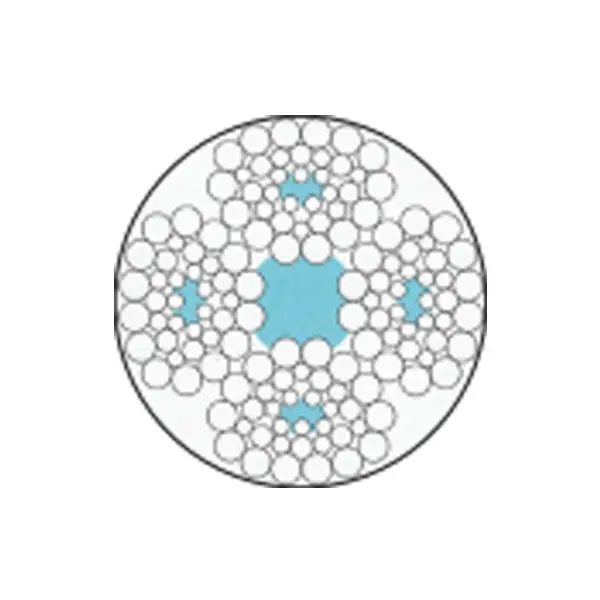

Plastic-coated steel wire rope is a high-performance lifting and handling tool widely used in various industrial fields.The wire ropes can be coated withTPU PP, PE, PVC, Nylon.Coating various diameter and all kinds of colour according to your request.

Precautions:

1.During transportation and storage, handle coated wire ropes with care to avoid damaging the coating. Store them in a dry, cool place to prevent degradation of the coating.

2.Conduct regular inspections to check for signs of wear, corrosion, or damage to the coating. Pay attention to areas where the rope is in contact with other surfaces, as this is where wear is most likely to occur.

3.Clean the rope regularly to remove dirt and debris that could cause wear or damage to the coating. Avoid using harsh chemicals that could degrade the coating.

4.Never exceed the rated breaking strength of the wire rope. Overloading can cause the coating to crack or peel, reducing its effectiveness.

5.Ensure that the coating material is compatible with the environment in which the rope will be used. For example, PVC coatings are suitable for general outdoor use, while nylon coatings may be preferred for applications with higher abrasion.

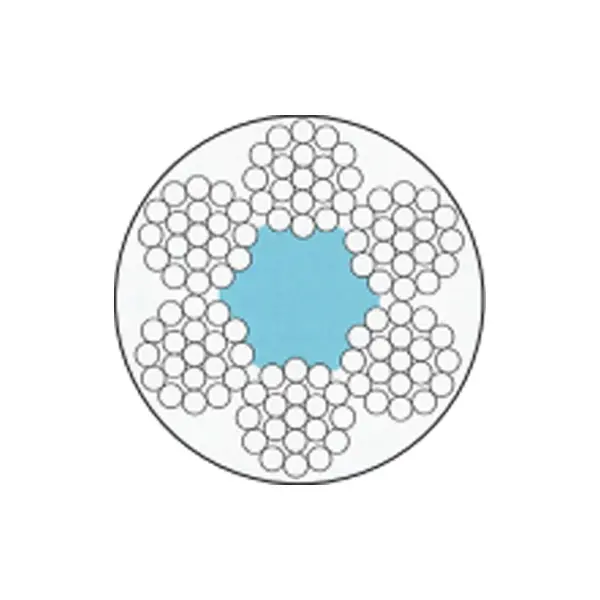

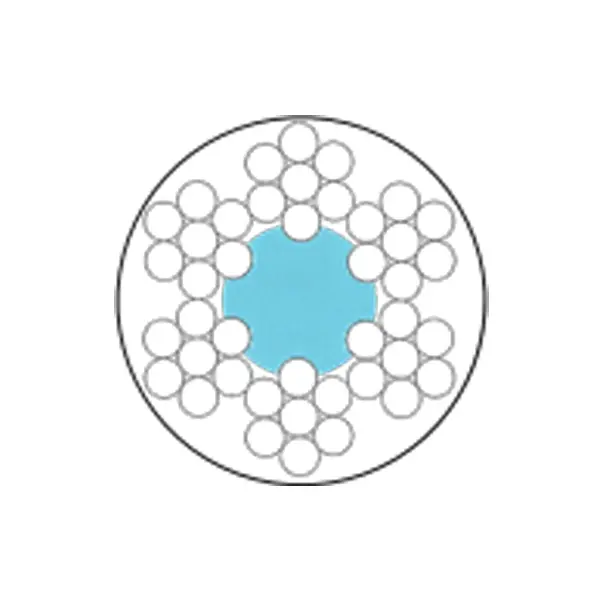

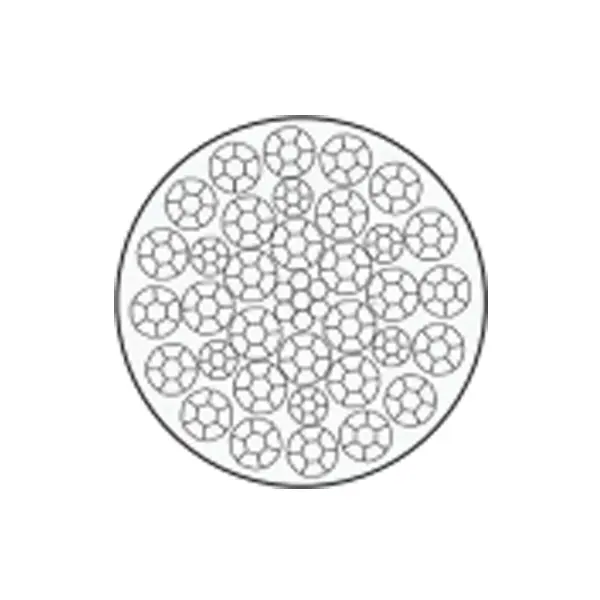

Galvanized Steel Wire Rope

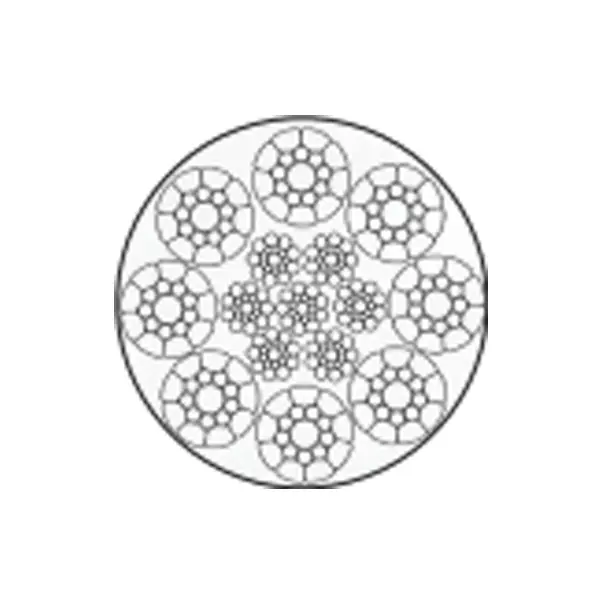

Galvanized steel wire ropes are made offine Carbon Steel Wire, There are Hot dip galvanized and Electric Galvanized wire rope,The galvanized wire ropes have higher tensile strength and better oxidation resistance than ungalvanized. widely used in lifting locks, car control cable, garage door lock, rein forcement cable etc.

Precautions:

1.Avoid dragging the wire rope on abrasive surfaces to prevent damage to the zinc coating. Store in a dry, well-ventilated area to prevent moisture buildup and corrosion.

2.Never exceed the recommended working load limit (WLL) to prevent overloading and potential failure. Ensure the wire rope is suitable for the specific application (e.g., lifting, towing, or rigging).

3.Regularly inspect for signs of wear, corrosion, broken wires, or deformation. Replace the wire rope if it shows significant damage or exceeds the allowable number of broken wires.

4.Use proper fittings, clamps, or end terminations to secure the wire rope. Avoid sharp bends or angles that can cause stress concentrations.

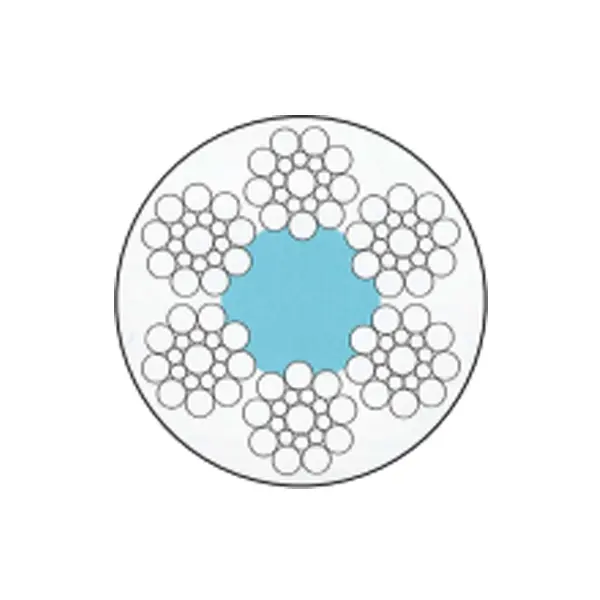

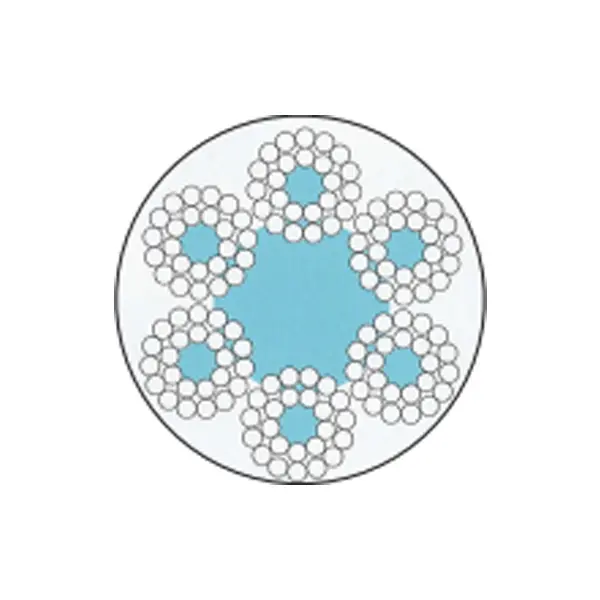

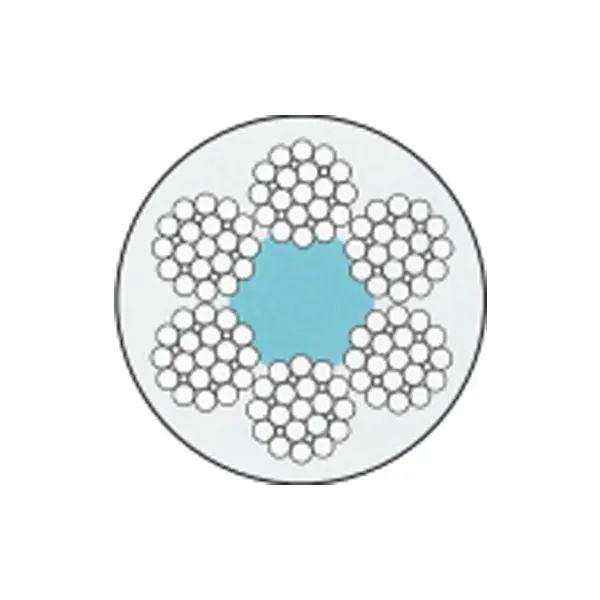

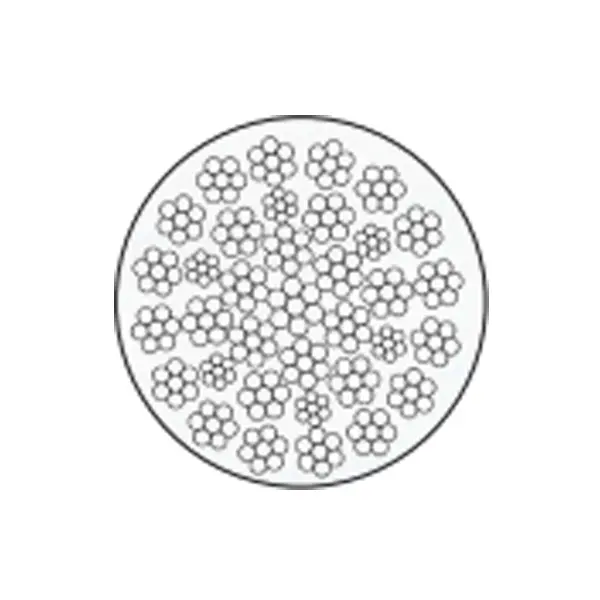

Stainless Steel Wire Rope

Stainless steel wire rope is made of high quality AISI304, AISI316 and other grades of stain less steel. It has excellent corrosion resistance, high temperature resistance and low temperature resistance.It is widely used in petrochemical industry.aviation, automobile, fishery. precision instruments and Building decoration and other industries.After the stainless steel wire rope is electropolished, the surface is brighter and the corrosion resistance is greatly increased. After low temperature treatment, the wire rope can achieve higher strength.

Precautions:

1.Never exceed the rated breaking strength of the wire rope. Always use appropriate safety factors (typically 5 or higher) to ensure the rope is not subjected to loads close to its breaking strength.

2.Ensure the wire rope is installed correctly to avoid kinks and sharp bends, which can weaken the rope. Use sheaves and drums with appropriate diameters to minimize bending stresses.

3.Conduct regular visual inspections to check for signs of wear, corrosion, broken wires, or deformation. Inspect areas where the rope contacts sheaves, drums, or other hardware.

4.Store stainless steel wire ropes in a dry, cool, and well-ventilated area to prevent corrosion. Avoid storing them in damp or humid environments.

Double Sides Dragging Cable Grip Type MGT

The Dual-Side Drawstring Mesh Guard, MGT, is a high-performance tool designed specifically for cable and pipeline protection. It combines robust materials, precision manufacturing processes, and user-friendly design to provide excellent protection and organization solutions.It adopts multi strand weaving, and the cable head can be threaded out for easy installation and connection. The double sided pull type cable grip is suitable for pulling and dragging heavy cables in the middle.The materials of cable grip can be divided into hot-dip galvanized, stainless steel 304, and stainless steel 316. The materials of the compression connection parts include aluminum alloy compression, stainless steel compression, and copper sleeve compression.

Nylon Cable Grip Type DWPG

The Nylon Mesh Sleeve DWPG (Durable Wire Protection Guard) is a high-performance tool specifically designed for cable and wire protection. It combines robust materials, precision manufacturing processes, and user-friendly design to provide an excellent solution for cable protection and organization.IIt adopts single or multi strand weaving, and the appearance can be customized according to customer requirements for single eye or single-sided pulling.

This insulated wire mesh grip is made of fiber material, which is lightweight. The sleeve can tightly adhere to the surface of the cable, effectively preventing the cable from being compressed and worn during prolonged lifting operations, thus providing excellent protection against damage

Single Stranded And Double-Sided Cable Grip Typ...

The Single-Side Drawstring Mesh Sleeve, MGS, is a high-performance tool specifically designed for cable and pipeline protection. It combines robust materials, precision manufacturing processes, and user-friendly design to provide excellent protection and organization solutions.It adopts single strand weaving, and the cable head can be threaded out, making it easy to install and connect. The double-sided pull type cable

grip is suitable for pulling and dragging the middle of the cable.The materials of cable grip can be divided into hot-dip galvanized, stainless steel 304, and stainless steel 316. The materials of the compression

connection parts include aluminum alloy compression, stainless steel compression, and copper sleeve compression.

Precautions:

1.Before use, ensure that the sleeve is correctly installed according to the manual, and check that all connections are secure.

2.Regularly inspect the sleeve for wear, breaks, or aging, and replace any damaged parts promptly.

3.Do not exceed the rated load capacity of the sleeve to prevent equipment damage or safety accidents.

4.When using and storing the sleeve, keep it dry and clean to avoid contact with oil, chemicals, and other harmful substances.

Feeder Line Hanging Net Type BD

Feeder Line Hanging Net is a specialized net designed to suspend, secure, and protect feeder line and related equipment. Its unique wrap-around structure makes it an essential tool in a variety of engineering and operational scenarios.

Purpose

In the field of communication engineering, it is mainly used for lifting and fixing the feeder line to ensure the stability of the feeder line during installation and maintenance, preventing it from being damaged due to factors such as swaying and external force impact. For example, in the construction of base stations, the feeder line is lifted from the ground to the corresponding position on the tower and fixed firmly to ensure the normal laying and operation of the communication lines.

In the field of electric power engineering, it can be used to assist lifting and fixing some electric power cables and related auxiliary equipment, ensuring the safe construction of electric power transmission lines and stable operation in the subsequent period.In addition, in installation and maintenance operations involving equipment such as cables, the Feeder Line Hanging Net can provide reliable support, fixing, and protection.

In addition, in installation and maintenance operations involving equipment such as cables, the Feeder Line Hanging Net can provide reliable support, fixing, and protection.

Double Sides Dragging Cable Grip Type WTG

The WTG net sleeve is a dual-sided pull cable net, the head can go through it, making it convenient to fix and hang the net head after pulling. It is of critical and diverse use for large high-voltage cables during undersea pulling construction.

When using hot-dip galvanized steel wire net sleeve, its excellent strength allows it to hold tightly onto large high-pressure cables in complex and harsh undersea environments. During undersea pulling operations, it can effectively prevent the cable from slipping, ensuring that it follows its predetermined undersea route steadily, thereby guaranteeing the continuity and precision of undersea cable laying projects. This enables power energy to be transmitted smoothly from land to various electrical facilities in the ocean, such as power supply systems on islands and offshore oil drilling platforms.

Change Line Cable Grip Type RB

Surface State

The surface of the change-of-line net sleeve is typically smooth. This design minimizes friction during use, whether in contact with the hoisted object's surface or when passing through pipes and holes. The smooth surface ensures seamless movement and prevents unnecessary wear on the cable or related components.

Core Type Classification

The change-of-line net sleeve is available in various core types to cater to different needs:

Single-Core Type: Ideal for hoisting and operating a single cable, providing stable support and protection by closely fitting the cable.

Multi-Core Type: Suitable for hoisting multiple cables simultaneously, accommodating them in an orderly manner. This facilitates centralized management, prevents cable entanglement, and streamlines operations.

Steel Wire Diameter

The steel wire diameter specifications vary:

Fine Steel Wire: Used for lightweight cables or scenarios requiring high flexibility.

Thicker Steel Wire: Employed for heavy-duty cables or in complex, harsh environments. The diameter directly affects the load-bearing capacity and strength of the net sleeve. Users should select the appropriate diameter based on the weight, length, and complexity of the cables involved.

Change Line Cable Grip Type RA

Surface State

The surface of the change-of-line net sleeve is usually smooth. This smooth surface design is intended to minimize friction during use, whether in contact with the surface of the object being hoisted or when passing through various pipes, holes, etc., to ensure smooth movement and avoid unnecessary wear on the cable or other related components.

Heavy Duty Feeder Line Hanging Net Type RAB

Feeder Line Hanging Nets are essential components in communication engineering, offering robust support and protection for the deployment and upkeep of communication lines. In contemporary communication infrastructure, these nets find extensive applications across diverse settings to guarantee the uninterrupted transmission of communication signals.

Crafted from high-tensile hot-dip galvanized steel wire rope and stainless steel rope, Feeder Line Hanging Nets boast excellent resistance to wear and corrosion. They are engineered to handle significant loads, ensuring the feeder's safety during lifting operations. Additionally, the design of these nets incorporates flexibility and adaptability, accommodating various installation contexts and requirements seamlessly.

Heavy Duty Feeder Line Hanging Net Type RAB

The Heavy-Duty Feeder Support Net RAB (Rapid Adjustable Bracket) is a high-performance tool specifically designed for the support and management of heavy cables. It combines robust materials, precision manufacturing processes, and user-friendly design to provide an excellent solution for cable protection and organization. It is mainly used for cable head traction and dragging, using single strand soft wire weaving with single eye type. The advantages are that the steel wire rope is highly flexible and elastic, making it easy to pass through the bending point.stainless steel 304, and stainless steel 316. The materials of the compression connection parts include aluminum alloy compression, stainless steel compression, and copper sleeve compression.